- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

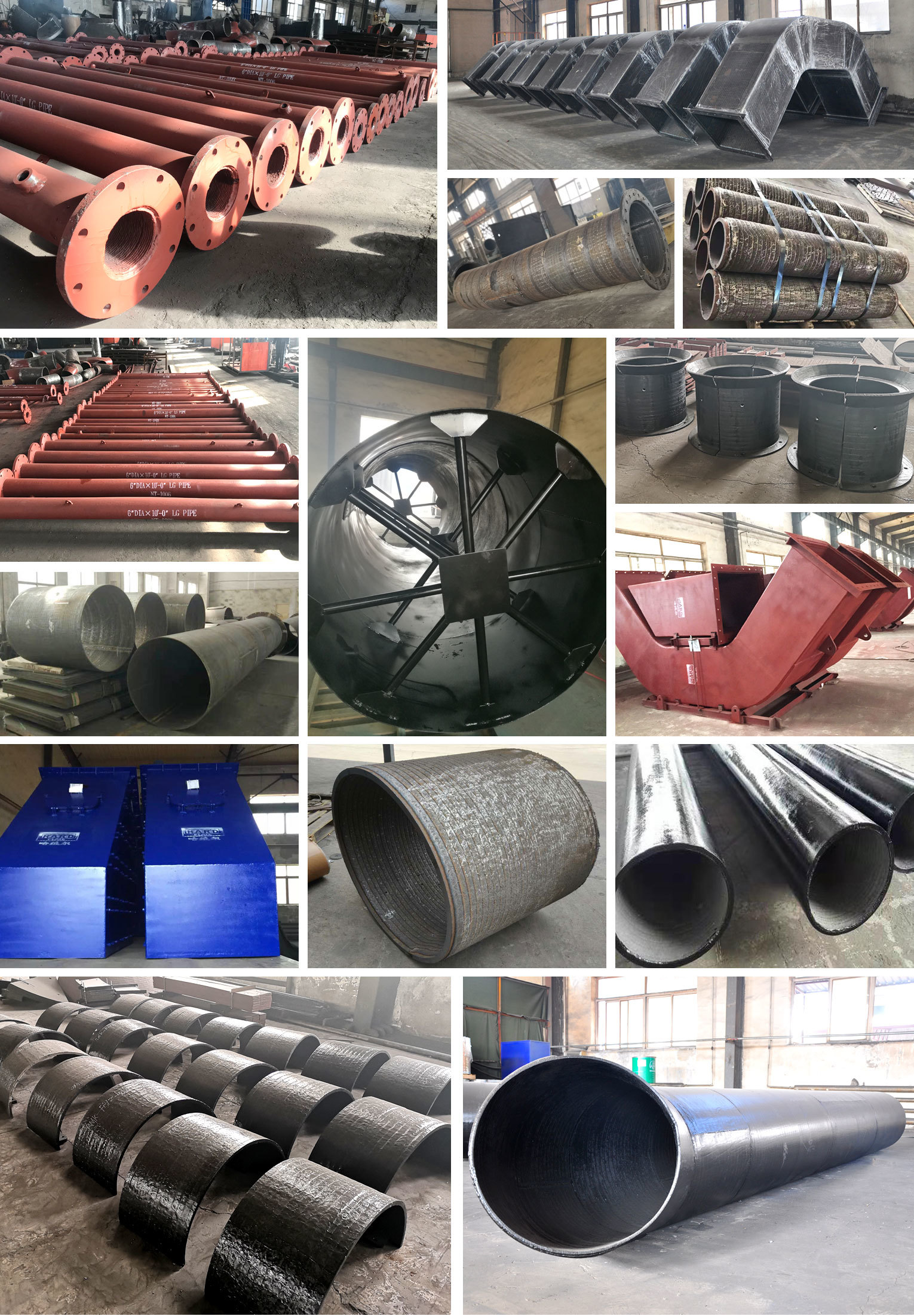

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

Unbreakable Connections-Exploring the Advancements of Wear-Resistant Pipelines and Elbows in Industrial Applications

2023-12-28 10:45

Wear-resistant pipes and elbows are crucial components in various industrial applications. These specialized pipes and elbows are designed to withstand harsh conditions, such as abrasive materials, high temperatures, and corrosive environments. This article explores the applications of wear-resistant pipes and elbows in industries, highlighting their importance and benefits.

In the mining industry, wear-resistant pipes and elbows are used extensively to transport abrasive materials such as coal, ore, and minerals. These abrasion resistant pipes are designed to withstand the constant impact and erosion caused by the movement of these materials. By utilizing wear-resistant pipes and elbows, mining operations can reduce maintenance costs, minimize downtime, and enhance overall efficiency.

2. Power Generation:

In thermal power plants, wear-resistant pipes and elbows are employed to transport coal and ash slurry. The high-pressure and high-temperature conditions in these systems subject the pipes and elbows to significant wear and tear. By using wear-resistant materials, power plants can ensure a reliable and uninterrupted flow of materials, thereby increasing the lifespan of the piping system.

3. Cement Industry:

The cement industry heavily relies on wear-resistant pipes and elbows for the transportation of abrasive materials, including limestone, clay, and gypsum. These materials can cause severe erosion and corrosion to standard pipes, leading to frequent replacements and maintenance. By utilizing wear-resistant pipes and elbows, cement plants can significantly reduce downtime, increase productivity, and improve cost-efficiency.

4. Steel Industry:

In the steel industry, wear-resistant pipes and elbows are used for the transportation of molten metal, slag, and other abrasive materials. The extreme temperatures and abrasive nature of these substances require pipes and bends that can withstand high thermal and mechanical stress. By utilizing wear-resistant pipes and elbows, steel plants can improve operational efficiency, reduce downtime, and extend the lifespan of their equipment.

Wear-resistant pipes and elbows play a vital role in various industries, ensuring the safe and efficient transportation of abrasive, corrosive, and high-temperature materials. By utilizing these specialized components, industries can minimize maintenance costs, reduce downtime, and improve overall productivity. The continuous development and use of chromium carbide overlay pipe and elbows contribute significantly to the advancement of industrial processes

Get the latest price? We'll respond as soon as possible(within 12 hours)