- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

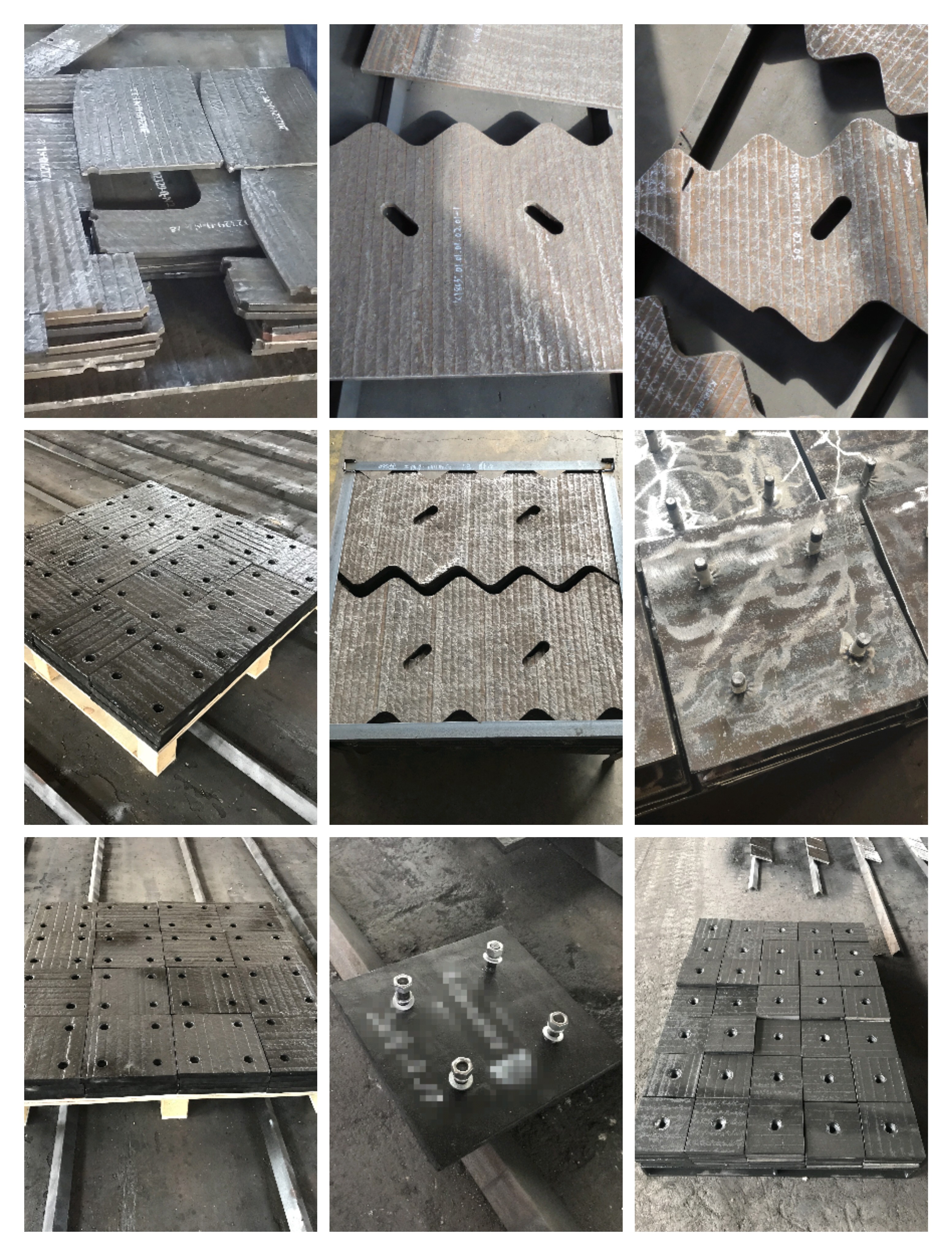

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

Shielding Your Equipment-The Power of Wear-Resistant Liner Plates

2023-12-25 14:13

Wear-resistant liner plates (alloy wear liner)are widely used in various industries to protect equipment and machinery from excessive wear and tear. These liner plates are specifically designed to withstand abrasive forces, impact, and corrosion, ensuring the longevity and performance of the underlying components.

The primary purpose of bimetallic Wear Resistant wear liner is to provide a protective barrier between the equipment and the abrasive materials or harsh environments they encounter. They are commonly used in industries such as mining, cement manufacturing, steel production, and power generation, where equipment is exposed to high levels of abrasion and impact.

One of the key benefits of wear-resistant liner plates is their ability to extend the lifespan of equipment. By acting as a shield against abrasive materials, these liner plates significantly reduce the wear on critical components, such as chutes, hoppers, crushers, and conveyor systems. This leads to reduced maintenance costs, increased productivity, and improved overall efficiency.

Moreover, wear-resistant liner plates offer excellent resistance to impact and corrosion. They are capable of withstanding heavy blows and shocks, thereby protecting the underlying equipment from damage. Additionally, their corrosion-resistant properties ensure that the equipment remains protected even in corrosive environments, such as chemical processing plants.

Another advantage of wear-resistant liner plates is their versatility in application. They can be customized to fit various equipment and machinery, ensuring a precise and secure fit. This adaptability allows for easy installation and replacement, minimizing downtime and maximizing productivity.

In terms of materials, wear-resistant liner plates are commonly made from high-quality alloys or composite materials. These materials are carefully selected for their exceptional hardness, toughness, and resistance to wear. They are engineered to withstand the most demanding conditions and provide long-lasting protection.

Furthermore, wear-resistant liner plates can be tailored to meet specific requirements. They are available in different thicknesses, sizes, and shapes, allowing for customization based on the equipment's needs. This ensures optimal performance and efficiency, as the bimetallic Wear Resistant wear linerare specifically designed to handle the unique challenges of each application.

In conclusion,bimetallic Wear Resistant wear liner play a crucial role in protecting equipment and machinery from excessive wear and tear. Their ability to withstand abrasion, impact, and corrosion ensures the longevity and performance of critical components. With their versatility and customization options, these wear liner plates provide a cost-effective and efficient solution for industries that face demanding operating conditions.

Get the latest price? We'll respond as soon as possible(within 12 hours)