- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

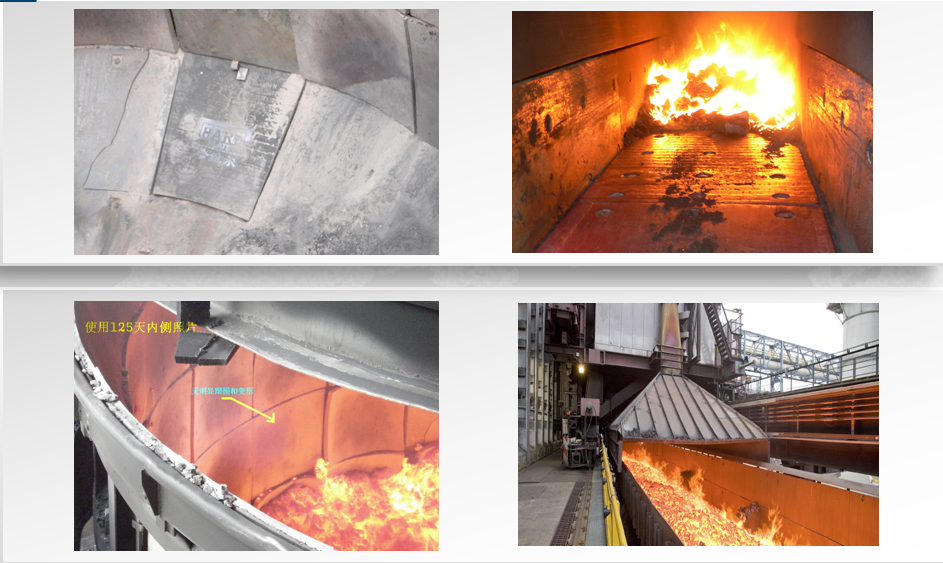

Boosting Efficiency in the Coal Sector with Wear-resistant Liners

2024-10-22 09:25

Wear-resistant lining plate is a crucial component in the coal industry, as it plays a significant role in protecting equipment and machinery from wear and tear caused by the abrasive nature of coal and other materials processed in coal plants. These lining plates are typically made from materials such as chromoim carbide overlay, ceramic, rubber, or metal alloys, which are known for their high resistance to abrasion.

In coal plants, wear-resistant lining plates are commonly used in various equipment and machinery, including chutes, hoppers, fan blade,crushers, and conveyor systems. These plates help to extend the lifespan of the equipment by reducing the impact of abrasion and prolonging the maintenance intervals. By preventing wear and tear, these lining plates also contribute to the overall efficiency and productivity of coal plants.

One of the key benefits of using wear-resistant lining plates in the coal industry is the reduction in downtime and maintenance costs. By protecting the equipment from abrasion, these plates help to minimize the need for frequent repairs and replacements, saving both time and money for coal plant operators. Additionally, the improved durability provided by these lining plates ensures a more reliable and consistent operation of the equipment, leading to increased productivity and profitability.

Overall, the application of wear-resistant lining plates in the coal industry is essential for maintaining the efficiency and longevity of equipment and machinery. With their ability to withstand abrasion and protect against wear and tear, these lining plates play a crucial role in ensuring the smooth operation of coal plants and enhancing their overall performance.

Get the latest price? We'll respond as soon as possible(within 12 hours)