- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

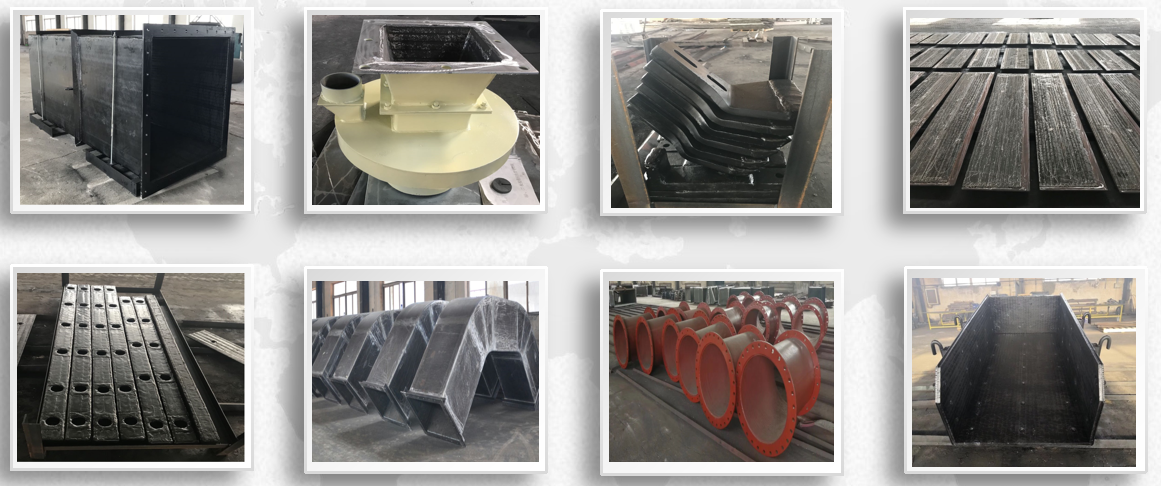

Customized Applications of Hardfacing Wear Parts in Industry

2024-11-05 09:18

Hardfacing wear parts (Chromium Carbide Overlay Wear Parts ) have become essential components in various industrial applications due to their exceptional durability and wear resistance. These parts, such as wear-resistant pipes, scraper blades, and impact plates, are commonly used in industries where abrasive materials are handled or high impact forces are present.

Wear-resistant pipes are widely used in industries such as mining, cement, and power generation, where materials such as ores, cement, and coal are transported through pipelines. These pipes are coated with hardfacing materials to protect against abrasion and corrosion, extending their lifespan and reducing maintenance costs.

Scraper blades, also known as harrow teeth or rake teeth, are commonly used in agricultural equipment, construction machinery, and mining equipment. These blades are subjected to high levels of wear and impact during operation, making hardfacing essential to ensure their longevity and performance.

Impact plates are another type of wear part that is crucial in industries such as recycling, quarrying, and construction. These plates are designed to withstand high impact forces from materials being processed, such as rocks, concrete, or metal scraps. Hardfacing these plates helps to minimize wear and prolong their service life.wear-resistant parts

One of the key advantages of hardfacing wear parts is the ability to customize them according to the specific requirements of customers. Manufacturers can tailor the hardfacing materials, thickness, and design of the parts to meet the unique needs of each application, ensuring optimal performance and longevity.

In conclusion, hardfacing wear parts play a vital role in various industrial applications, providing superior wear resistance and durability. Whether it is wear-resistant pipes, scraper blades, or impact plates, these parts can be customized to meet the specific demands of customers, making them essential components in the industrial sector.

Get the latest price? We'll respond as soon as possible(within 12 hours)