- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

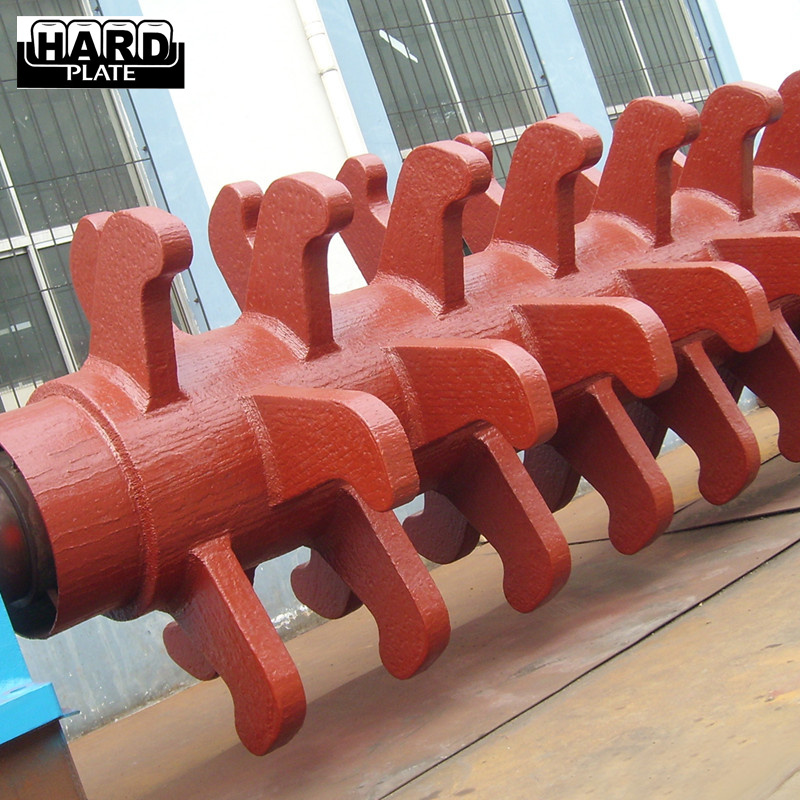

"The Durability of Single Tooth Rollers"

2024-03-15 13:14

Wear-resistant single tooth roller is a type of industrial component commonly used in various machinery and equipment for material handling and processing. This specialized roller is designed to withstand high levels of wear and tear, making it ideal for applications that involve heavy-duty operations.

One of the key features of a wear-resistant single tooth roller is its durability. These rollers are typically made from high-quality materials such as hardened steel or alloy steel, which are known for their strength and resistance to abrasion. This allows the roller to maintain its shape and functionality even under harsh working conditions, ensuring long-lasting performance and reducing the need for frequent replacements.

In addition to durability, wear-resistant single tooth rollers also offer excellent performance in terms of material handling. The single tooth design allows for efficient and effective gripping and conveying of materials, making them suitable for applications such as crushing, grinding, and transporting heavy loads. The wear-resistant surface of the roller ensures smooth operation and minimal friction, leading to increased productivity and reduced maintenance costs.

Furthermore, wear-resistant single tooth rollers are easy to install and maintain, making them a cost-effective solution for industries that require reliable and efficient material handling equipment. With proper care and regular maintenance, these rollers can provide years of reliable service, contributing to the overall efficiency and productivity of the machinery in which they are used.

In conclusion, wear-resistant single tooth rollers are essential components in various industrial applications where durability, performance, and efficiency are key requirements. Their ability to withstand wear and tear, along with their superior material handling capabilities, make them a valuable asset for industries that rely on heavy-duty machinery and equipment. With their long lifespan and low maintenance requirements, wear-resistant single tooth rollers are a smart investment for businesses looking to optimize their material handling processes.

Get the latest price? We'll respond as soon as possible(within 12 hours)