- Home

-

Products

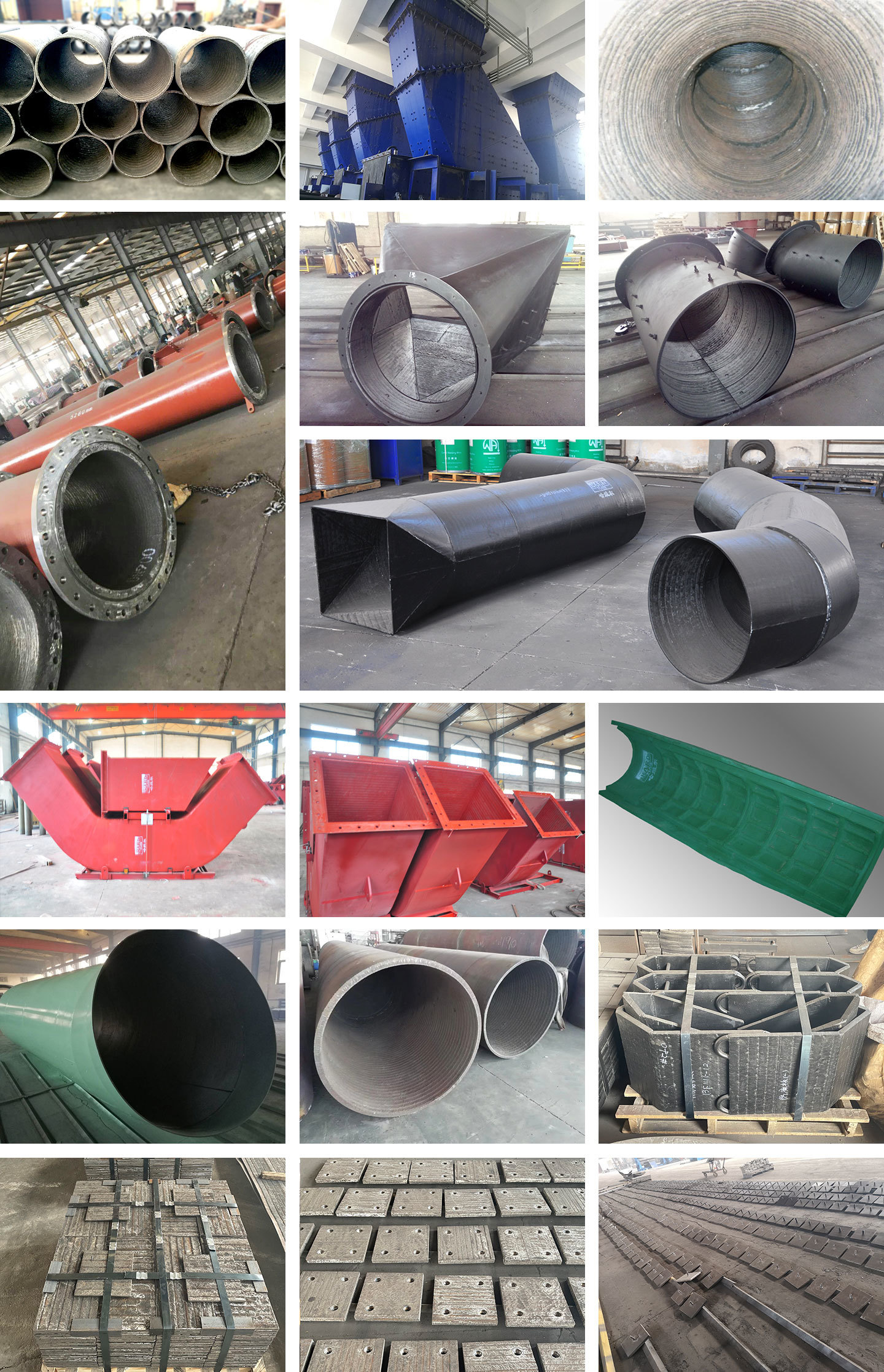

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

"The Importance of Wear Parts in the Port Industry"

2024-03-13 13:58

In the port industry, wear-resistant components play a crucial role in ensuring the smooth operation of equipment and machinery. Ports are bustling hubs of activity, with heavy machinery and equipment constantly in use to load and unload cargo, transport containers, and maintain infrastructure. The wear and tear on equipment in this environment can be significant, making the use of wear-resistant components essential for optimal performance and longevity.

One of the key areas wherewear-resistant components are utilized in the port industry is in material handling equipment, such as cranes, conveyors, and forklifts. These machines are subjected to constant friction, impact, and abrasion during their operation, leading to wear on critical components such as gears, bearings, and hydraulic systems. By incorporating wear-resistant materials such as hardened steel, ceramic coatings, or specialized polymers, the lifespan of these components can be extended, reducing downtime and maintenance costs.

Another important application of wear-resistant components in the port industry is in shipbuilding and repair. Ports often have dry docks and shipyards where vessels undergo maintenance, repairs, and refurbishment. Wear-resistant materials are used in various components of ships, such as propellers, shafts, and valves, to withstand the harsh marine environment and ensure the safety and efficiency of maritime operations.

Furthermore, wear-resistant components are also utilized in port infrastructure, such as dock fenders, bollards, and mooring systems. These components are subjected to constant impact and abrasion from vessels during docking and berthing operations. By using wear-resistant materials and coatings, these components can withstand the heavy loads and harsh conditions, ensuring the safety and reliability of port operations.

In conclusion, wear-resistant components play a vital role in the port industry by enhancing the durability, performance, and safety of equipment and infrastructure. By investing in high-quality wear-resistant materials and components, ports can improve operational efficiency, reduce maintenance costs, and ensure the smooth and reliable functioning of their operations.

Get the latest price? We'll respond as soon as possible(within 12 hours)