- Home

-

Products

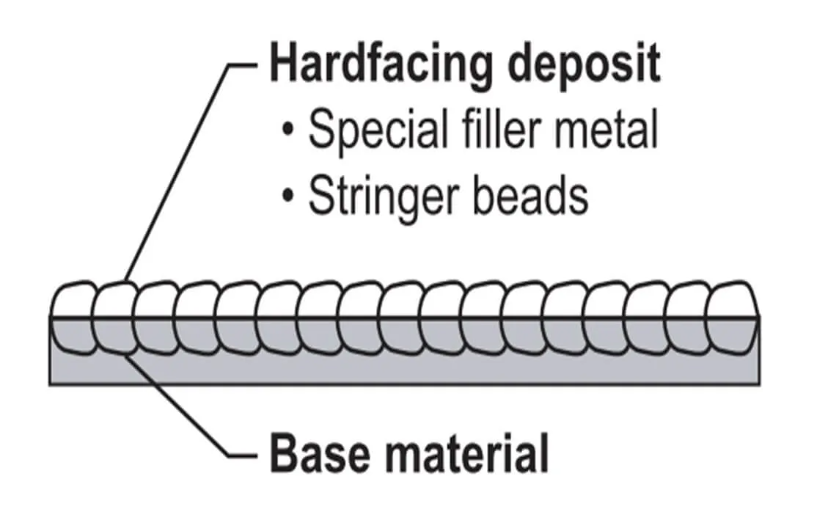

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

How to Test the Quality of Chromium Carbide Wear Plates?

2024-01-04 15:22

Chromium carbide wear plates are widely used in various industries for their excellent wear resistance properties. To ensure the quality of these plates, it is important to conduct proper testing. Here are some methods to test the quality of chromium carbide wear plates:

1. Hardness Testing: Measure the hardness of the wear plate using a hardness tester. The hardness of chromium carbide wear plates is typically measured using the Rockwell C scale (HRC). The higher the hardness value, the better the wear resistance. Compare the measured hardness with the specified hardness value provided by the manufacturer.

2. Wear Resistance Testing: Perform wear resistance testing to evaluate the ability of the wear plate to withstand abrasive wear. This can be done using various methods such as the ASTM G65 test or the Taber Abrasion test. These tests simulate the wear conditions that the wear plate may encounter in real-world applications. Compare the wear resistance results with the manufacturer's specifications or industry standards to determine the quality of the wear plate.

3. Adhesion Testing: Check the adhesion strength of the chromium carbide coating on the base material. This can be done by conducting a cross-cut adhesion test or a pull-off adhesion test. The coating should adhere firmly to the base material without any signs of delamination or detachment.

4. Chemical Composition Analysis: Analyze the chemical composition of the wear plate to ensure it meets the required specifications. This can be done using techniques such as X-ray fluorescence (XRF) or energy-dispersive X-ray spectroscopy (EDX). The composition should match the specified levels of chromium carbide and other alloying elements.

5. Microstructure Examination: Examine the microstructure of the wear plate under a microscope. A high-quality chromium carbide wear plate should have a fine and uniform distribution of carbides in the matrix. Any signs of carbide clustering or uneven distribution may indicate poor quality.

6. Impact Testing: Conduct impact testing to assess the toughness and impact resistance of the wear plate. This can be done using a Charpy or Izod impact test. The wear plate should demonstrate good resistance to cracking or fracturing upon impact.

It is important to note that these testing methods should be performed by trained professionals using appropriate equipment and following standardized procedures. Additionally, consulting with the manufacturer or industry experts can provide valuable insights into the specific testing requirements for chromium carbide wear plates.

Get the latest price? We'll respond as soon as possible(within 12 hours)