- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

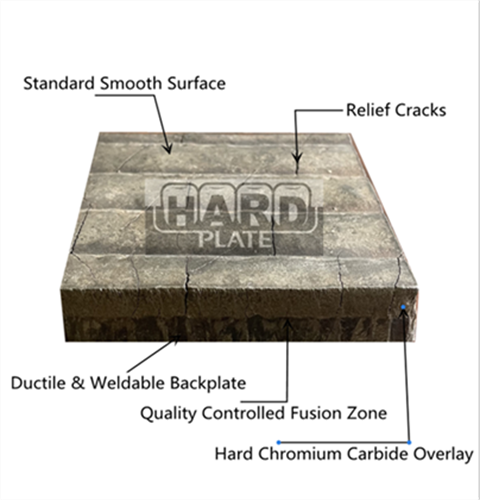

Why the chromium carbide overlay steel plate has so many cracks?

2023-11-01 14:46

The surface crack of the wear-resistant steel plate is the ability of the surface of the wear-resistant layer to release the surface of the wear-resistant layer by forming a fine and uniform crack, keeping the whole plate surface flat and limiting the stress concentration, and the crack is only limited to the hard layer, and the use process will not expand to the substrate with good toughness. Due to the cooling rates of dissimilar metals. Our wear-resistant steel plate is manufactured by welding which results in high temperatures. During the cooling, the plate goes through a stress relieving which is a natural process and does not effect the performance of the plate. The stress relief cracks should be between 3/4" - 2" apart.

Application conditions of wear-resistant steel plate: Wear-resistant steel plate can be suitable for working conditions below 550 °C, with high erosion wear and abrasive wear, and has good wear resistance, impact resistance and good oxidation resistance. Suitable for a wide range of wear conditions. Surface strengthening of various wear and tear equipment parts in the industry.

Typical applications are: This kind of wear-resistant steel plate is directly blanked, rounded and welded into various wear-resistant conveying pipelines with composite plates. Such as powder air conveying system, blast furnace slag system; According to the design requirements, users are provided with wear-resistant accessories made of composite plates, such as mill liners, mixer blades, fan blades, etc.; Directly provide composite steel plates to users, and users will cut materials by themselves and complete on-site construction projects by tailored welding. Such as silo, chute, etc.; According to the size of the wear area of the user's parts, prefabricated units are provided for on-site tailored welding. Reduce on-site welding workload. Such as the bucket of construction machinery and the dredger bucket of dredger; The tensile and impact resistance of the composite steel plate is not lower than the performance of the welded joint of the Q235 steel plate. The wear resistance of wear-resistant steel plate is 18-22 times that of low-carbon steel, 6-8 times that of stainless steel and high-manganese steel, and more than 1.5 times that of ordinary high-carbon steel plates.

Get the latest price? We'll respond as soon as possible(within 12 hours)