- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

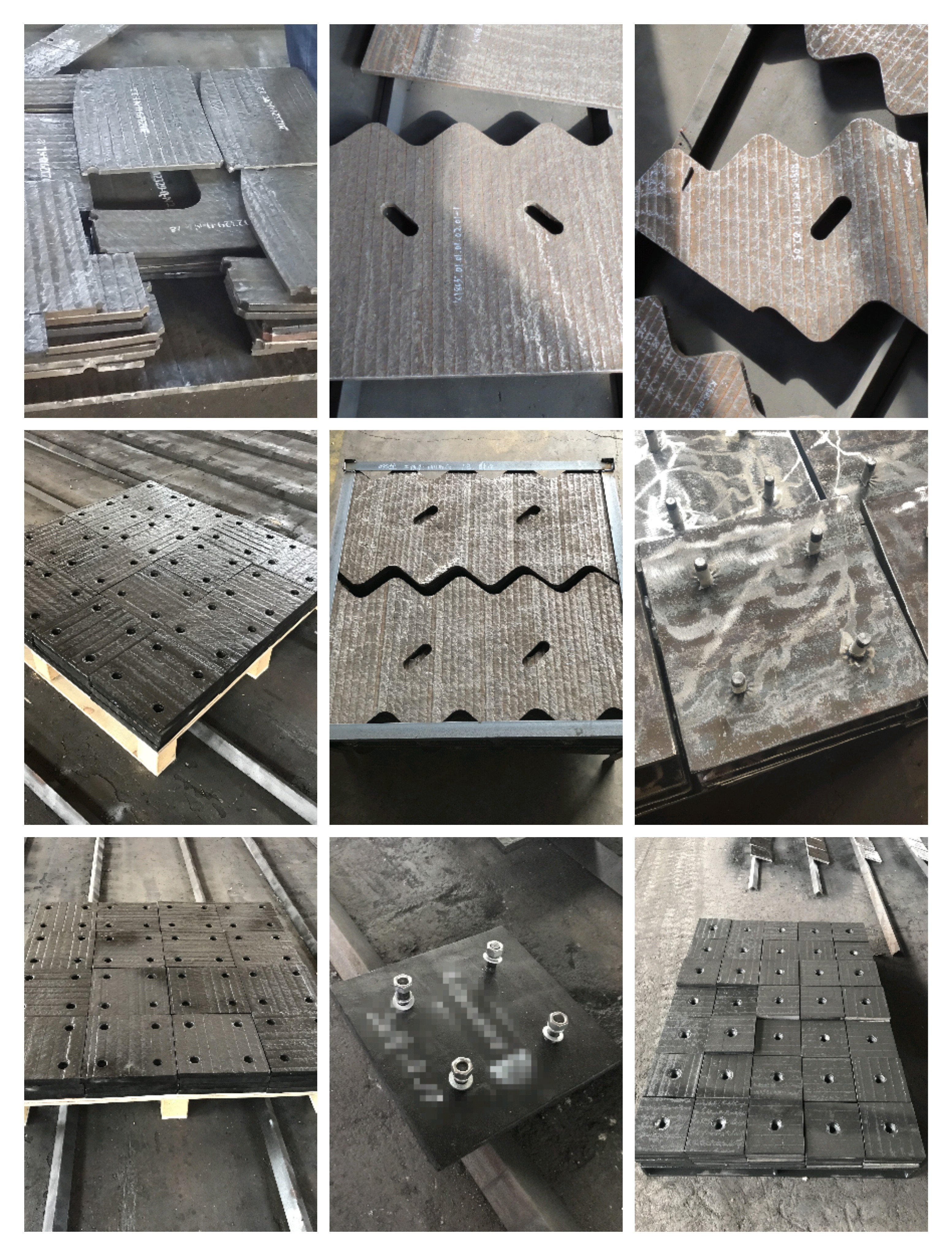

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

Wear-resistant steel plate introduction

2024-02-23 09:34

Wear-resistant steel plate is a special plate product used for large area wear conditions. Commonly used wear-resistant steel plate is in the toughness, good plasticity of ordinary low carbon steel or low alloy steel surface through the surfacing method of composite thickness of higher hardness, excellent wear resistance alloy wear layer and made of plate products. In addition, there are cast wear-resistant steel plate and alloy quenching wear-resistant steel plate.

Wear-resistant steel plate structure characteristics

Wear-resistant steel plate consists of low carbon steel plate and alloy wear-resistant layer of two parts, alloy wear-resistant layer is generally 1/3 ~ 1/2 of the total thickness. work by the matrix to provide resistance to external forces of strength, toughness and plasticity and other comprehensive performance, by the alloy wear-resistant layer to provide to meet the needs of specified conditions of the wear-resistant properties.

Wear-resistant steel plate alloy wear-resistant layer and the substrate is a metallurgical combination. Through special equipment, using automatic welding process, high hardness self-protection alloy wire uniformly welded on the substrate, the number of composite layers of one layer to two layers to multi-layer, the composite process due to the alloy shrinkage ratio is different, there is a uniform transverse crack, which is a significant feature of the wear-resistant steel plate.

Alloy wear-resistant layer is mainly dominated by chromium alloy, but also add manganese, molybdenum, niobium, nickel and other alloy components, the metallographic organization of carbide was a fibrous distribution, the direction of the fibers perpendicular to the surface. Carbide microhardness can reach HV1700-2000 above, alloy carbide at high temperatures has a strong stability, maintain high hardness, but also has good oxidation resistance, within 500 ℃ completely normal use.

Application scope of wear-resistant steel plate

Wear-resistant steel plate has high wear resistance and good impact properties good, able to cut, bend, weld, etc., can be taken to weld, plug welding, bolting and other ways to connect with other structures, in the maintenance of the site process of time-saving, convenient and so on, is widely used in metallurgy, coal, cement, electric power, glass, mining, building materials, masonry, etc., and other materials, has a high cost-effective price compared to other materials, has been favored by more and more industries and manufacturers.

Get the latest price? We'll respond as soon as possible(within 12 hours)