- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

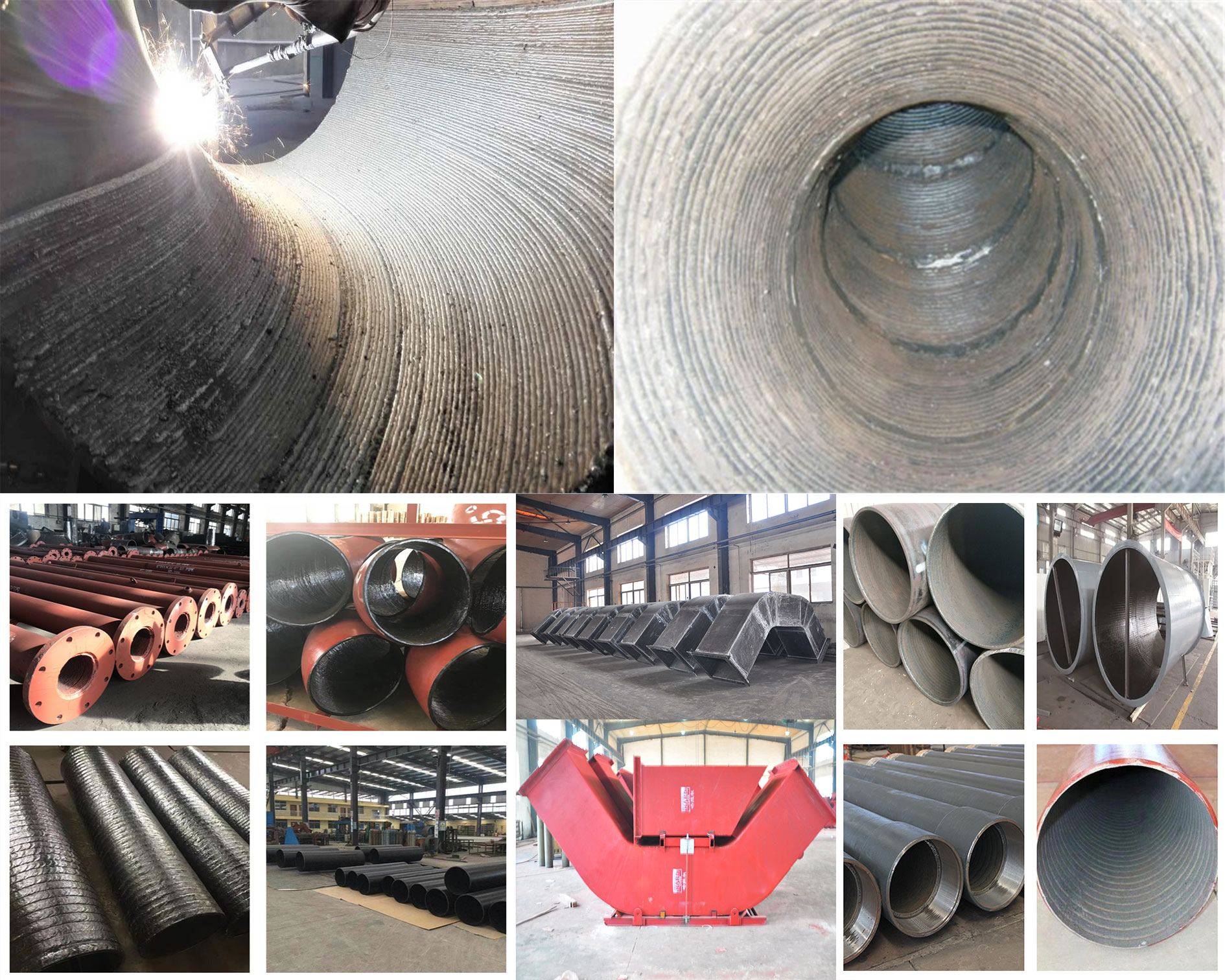

Performance Characteristics of Chromium Carbide Cladding Wear-Resistant Pipes

2024-08-15 16:44

Chromium carbide cladding wear-resistant pipe is a pipe made of chromium carbide material for cladding processing, which has high wear resistance. Carbide is a very hard alloy material with excellent wear resistance and corrosion resistance, suitable for use in high wear environments.

Chromium carbide cladding wear-resistant pipes are usually used in pipeline systems for conveying abrasive materials, such as ore, coal, cement, etc. It can effectively extend the service life of the pipeline, reduce the frequency of maintenance and replacement, and reduce production costs.

The manufacturing process of chromium carbide cladding wear-resistant pipes is relatively complicated, and requires precise cladding processing and heat treatment and other process steps. Therefore, its manufacturing cost is relatively high, but it can bring obvious economic and environmental benefits in long-term use.

Get the latest price? We'll respond as soon as possible(within 12 hours)