- Home

-

Products

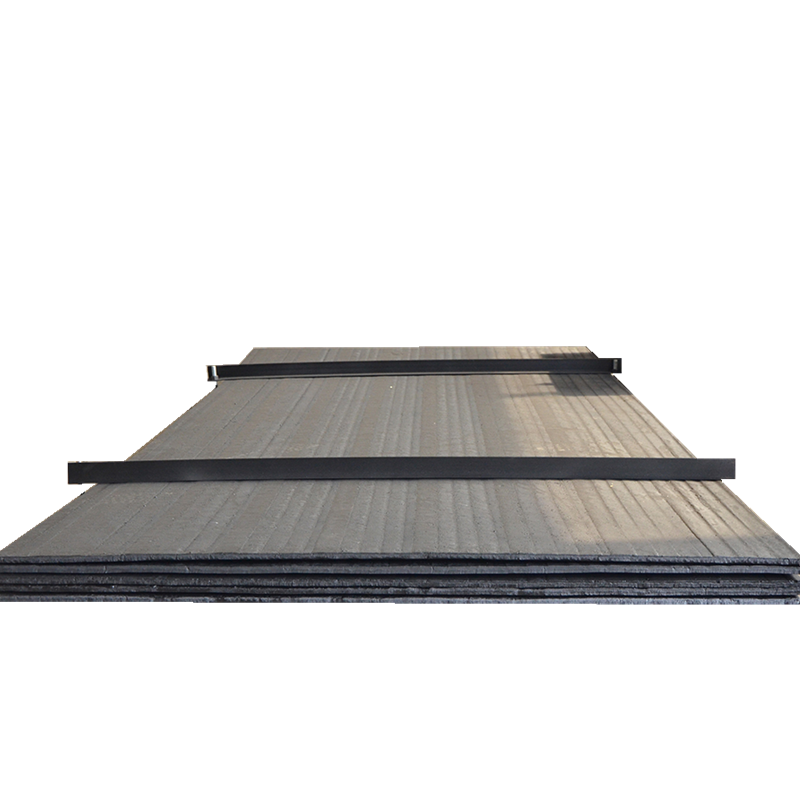

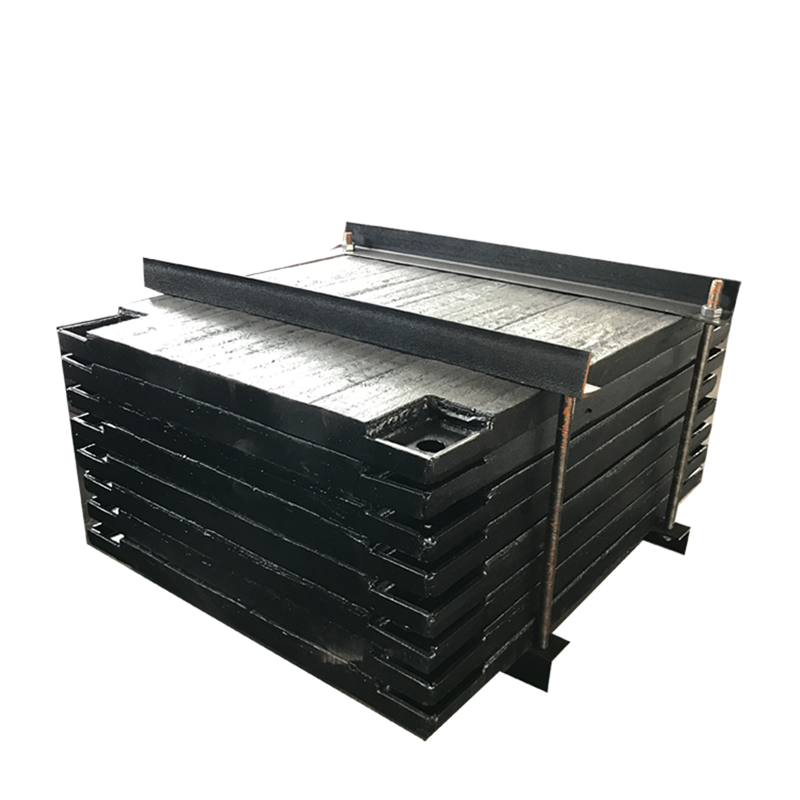

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

Manufacturing Process of Chromium Carbide Wear Resistant Steel Plate

2023-12-04 15:22

The manufacturing process of chromium carbide wear resistant steel plate involves several steps. Here is a general outline of the process:

1. Material Selection: The first step is to select high-quality base materials for the steel plate. Typically, a low carbon steel plate is chosen as the base material due to its excellent weldability and formability.

2. Overlay Preparation: The next step is to prepare the overlay material, which consists of chromium carbide particles embedded in a matrix. The chromium carbide particles provide the wear resistance, while the matrix material provides the toughness and bonding strength.

3. Overlay Application: The overlay material is applied to the base material using various methods such as submerged arc welding, open arc welding, or plasma transfer arc welding. During the application process, the overlay material is deposited in multiple layers to achieve the desired thickness and wear resistance.

4. Cooling and Solidification: After the overlay application, the steel plate is allowed to cool and solidify. This process is crucial to ensure proper bonding between the overlay and the base material.

5. Post-Treatment: Once the steel plate has cooled, it undergoes post-treatment processes to enhance its properties. This may include heat treatment, stress relieving, and surface finishing to improve hardness, toughness, and surface smoothness.

6. Quality Control: Throughout the manufacturing process, rigorous quality control measures are implemented to ensure the final product meets the required specifications. This includes testing the hardness, adhesion, and wear resistance of the chromium carbide wear resistant steel plate.

7. Cutting and Fabrication: The final step involves cutting the steel plate into the desired shapes and sizes, according to the specific application requirements. These plates can be further fabricated into various components such as liners, wear plates, or other wear resistant parts.

It is important to note that the manufacturing process may vary depending on the specific manufacturer and their proprietary techniques. However, the general steps outlined above provide an overview of the typical process involved in producing chromium carbide wear resistant steel plates.

Get the latest price? We'll respond as soon as possible(within 12 hours)