- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

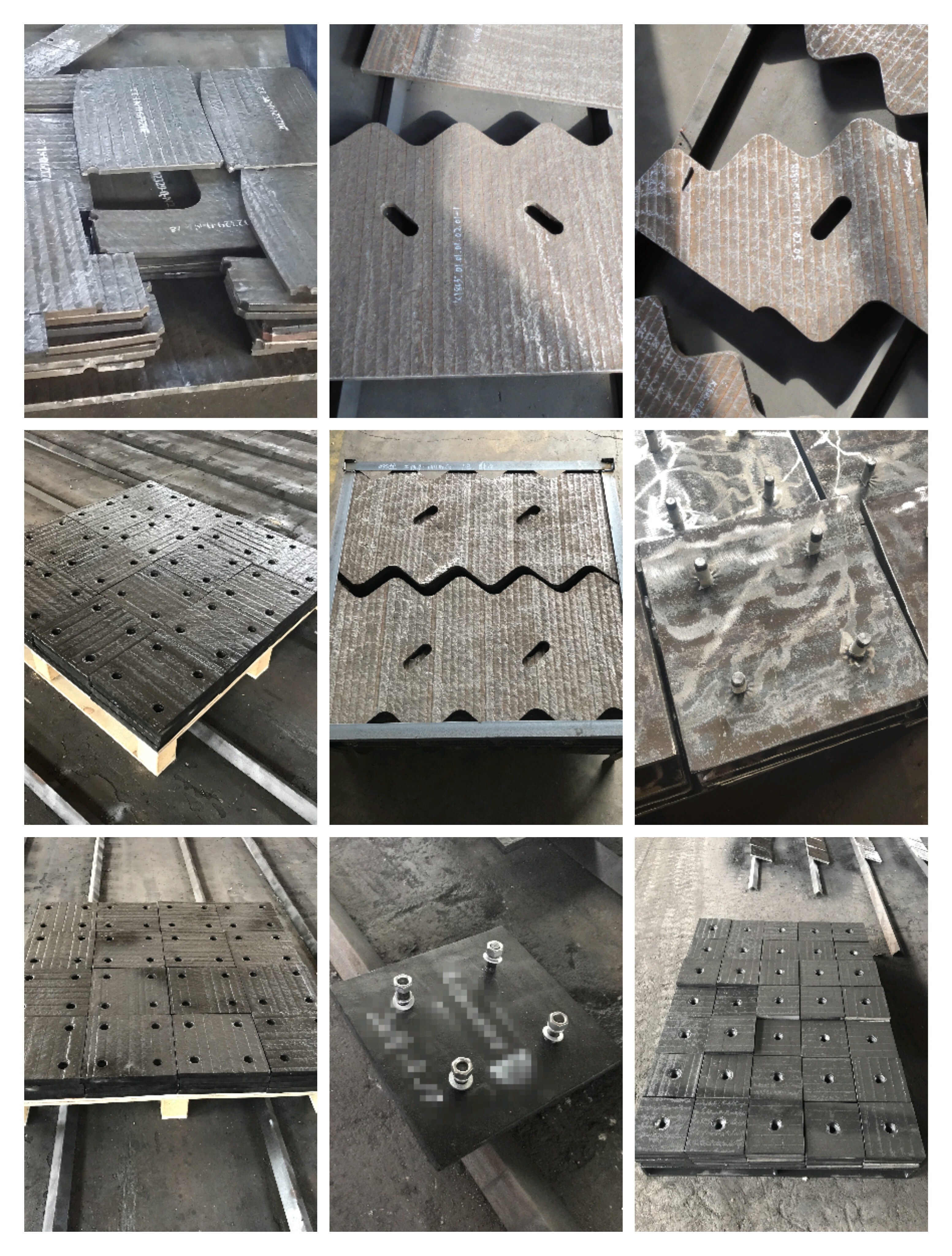

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

How to choose wear-resistant liner?

2023-11-09 15:25

Wear-resistant linerrefers to the wear-resistant steel plate processed by cutting, coil deformation, perforation and welding, etc., into various wear-resistant liners, such as conveyor liner, coal feeder bottom plate/cyclone inverted cone With liners, wear-resistant blades, etc., wear-resistant life can be increased by more than 15 times compared with ordinary steel plates.

The wear-resistant steel plate used to make the wear-resistant steel plate is an alloy wear-resistant layer mainly composed of Cr7C3 carbides with a volume fraction of more than 50% by surfacing welding on ordinary steel plates, heat-resistant steel plates, and stainless steel plates.

Wear-resistant steel platehas the properties of high wear resistance, impact resistance, deformability and weldability. It can be directly processed like steel plate by crimping, cutting and punching, and processed into engineering parts to meet the wearable industrial and mining use.

Compared with many wear-resistant materials, wear-resistant composite steel plates have their irreplaceable salient features:

1. The chemical composition of the high wear resistance alloy layer contains carbon content of 4~5%, chromium content as high as 25~30%, the volume fraction of Cr7C3 carbide in its metallographic structure reaches more than 50%, and the macroscopic hardness is HRC56~62 , The hardness of chromium carbide is HV1400~1800, which is higher than the hardness of quartz in sand and rock HV800~1200. Because the carbides are distributed vertically in the direction of wear, even when compared with cast alloys of the same composition and hardness, the wear resistance is more than doubled. The comparison of wear resistance with several typical materials is as follows:

(1) and low carbon steel; 20~25:

(2) and high manganese steel; 5~10:

(3) and tool steel; 5~10:

(4) and as-cast high chromium cast iron; 1.5~2.5:

2. Good impact resistance: The bottom layer of the wear-resistant composite steel plate is low-carbon steel or low-alloy. Tough materials such as stainless steel reflect the superiority of bimetal. The wear-resistant layer resists the wear of the wear medium, and the substrate bears the load of the medium, so it has good impact resistance. It can withstand the impact and wear of the high drop hopper in the material conveying system.

3. Better heat resistance: The wear-resistant layer is recommended to be used under ≤600℃. If vanadium, molybdenum and other alloys are added to the alloy layer, it can withstand high temperature wear at ≤800℃. The recommended operating temperature is as follows: Ordinary carbon steel substrate is recommended to be used under 380℃; low alloy heat-resistant steel plate (15CrMo, 12Cr1MoV, etc.) is recommended to be used under 540℃; heat-resistant stainless steel substrate is recommended to be used under Use at 800 ℃.

4. The alloy layer of the wear-resistant composite steel plate with good corrosion resistance contains a high percentage of metallic chromium, so it has certain anti-rust and corrosion resistance capabilities. It can be used to prevent coal sticking when used in coal dropping drums and hoppers.

5. The wear-resistant composite steel plate with strong applicability has complete specifications and many varieties, and has become a commercial series. The thickness of the wear-resistant alloy layer is 3-20mm. The thickness of the composite steel plate is at least 6mm, and the thickness is not limited. At present, the standard wear-resistant composite steel plate is available in 1200 or 1450×2000mm, and it can also be customized according to user requirements and according to the size of the drawing. Wear-resistant composite steel plates are now divided into three types: ordinary type, impact-resistant type and high-temperature type. Ordering high-temperature wear-resistant and impact-resistant composite steel plates shall be explained.

6. Convenient processing performance The wear-resistant composite steel plate can be cut, leveled, punched, bent and curled, and it can be made into flat plates, arc plates, cone plates, and cylinders. The cut composite board can be tailor-welded into various engineering structural parts or parts. The composite board can also be heated and pressed into a complex shape with a die. The wear-resistant composite steel plate can be fixed on the equipment by bolts or welding, which is convenient for replacement and maintenance.

7. High price performance. Although the manufacturing cost of the wear-resistant composite steel plate is increased, the service life is increased several times, which greatly reduces the maintenance cost and downtime loss. Its price performance is about 2 to 4 times higher than that of ordinary materials. The greater the material handling capacity, the more serious the equipment wear and tear, the more obvious the economic effect of using wear-resistant composite steel plates. Wear-resistant liner refers to the wear-resistant stee

Get the latest price? We'll respond as soon as possible(within 12 hours)