- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

How much do you know about high-temperature heat-resistant and wear-resistant steel plates?

2023-11-21 14:41

Refers to high-temperature wear-resistant steel plates, everyone may not know very well. In view of this, we will give you a brief introduction, hoping to bring some knowledge to consumers.

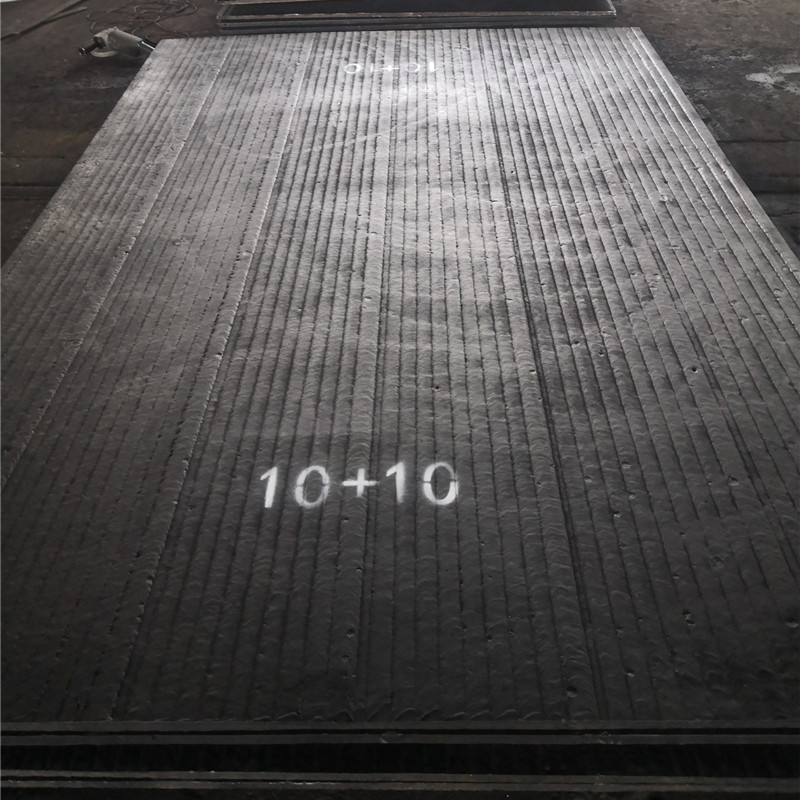

High-temperature wear-resistant steel plateis a plate used in large-area wear conditions. It is formed by hardfacing welding on ordinary steel plates, heat-resistant steel plates, and stainless steel plates to form alloy wear-resistant layers with a volume fraction of more than 50% Cr7C3 carbides. Wear-resistant steel plates have high wear resistance, impact resistance, deformability and weldability. They can be processed into engineering parts like steel plates, such as crimping, cutting and punching, and processed into engineering parts to meet the needs of wear-resistant industrial and mining operations.

High-temperature wear-resistant steel plateis a kind of wear-resistant composite material produced by advanced composite manufacturing technology. The wear-resistant layer is made of high-grade wear-resistant alloy, which is an advanced wear-resistant composite material in the industrial field.

Using the alloy system commonly used in the international wear-resistant composite steel plate, it has excellent resistance to abrasive wear. The method of metallurgical fusion is used to achieve metallurgical bonding between the wear-resistant layer and the substrate. The thickness of the wear-resistant layer is 3.5~12mm, the wear resistance is much higher than heat-treated wear-resistant steel and cast wear-resistant cast iron, and the wear resistance is much higher than spray welding or thermal spraying methods;

Since the base plate of the high temperature heat-resistant and wear-resistant steel plate adopts a low-carbon steel plate with good plasticity, it can absorb energy during the impact process. Therefore, the wear-resistant composite steel plate has strong impact resistance and crack resistance, and can be applied to vibration , Under strong impact conditions; high-temperature wear-resistant steel plates can be made into standard size steel plates, which are light in weight and convenient and flexible in processing. Due to the soft substrate, it can be cold-formed inward, and can be cut with plasma arc, carbon arc and other heat sources. It can be tailor-welded to shape, making the field welding work time-saving and convenient. Therefore, this material is in line with the current mainstream international manufacturing that uses welded structures instead of cast structures to reduce the weight of the structure.

Get the latest price? We'll respond as soon as possible(within 12 hours)