- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

Chromium Carbide Welding Wear Single Roller Crusher Teeth

The Chromium Carbide Welding Wear Single Roller Crusher Teeth are designed to enhance the crushing process by effectively gripping and breaking down the material. As the roller rotates, the teeth make contact with the material, applying pressure and gradually breaking it into smaller, more manageable pieces. This innovative design ensures efficient crushing and optimal performance, enhancing the overall productivity of your crusher.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Chromium Carbide Welding Wear Single Roller Crusher Teeth

Overview:

The Chromium Carbide Welding Wear Single Roller Crusher Teeth are installed on the roller of the crusher equipment.

As the roller rotates, these teeth come into contact with the material being crushed, effectively breaking it down into smaller pieces.

The chromium carbide material ensures exceptional hardness, allowing for efficient crushing even of the toughest materials.

Applications:

| Product Name | Chromium Carbide Welding Wear Single Roller Crusher Teeth |

| Base Material | ZG45/Q235/Q345+Chromium carbide overlay |

| Thickness | 3+3,5+5,6+4,6+5,8+4,8+8,10+10,16+10,etc |

| Chemical composition | C:3.0-5.0%Cr:25-40% |

| Technology | Hardfacing,open arc welding,submerged arcwelding |

| Flatness tolerance | ±3 mm/m |

| Thickness tolerance | uniform overlay thickness, with tolerance within 0-0.5 mm |

| Wear resistance | High wear/abrasion resistance |

| product Size | Customized sizes |

| Main Application | Mining, Steel, Cement, Power, Port, Glass, Coal, etc. |

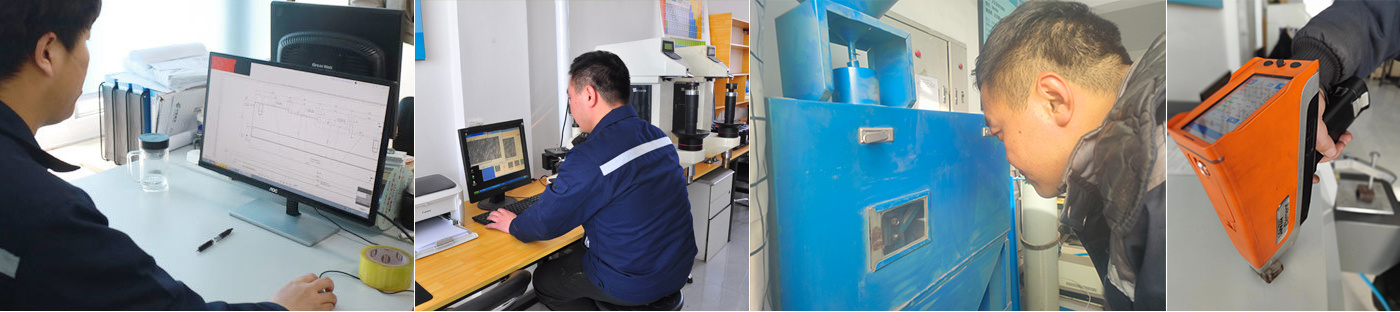

R & D ABILITY

♦Liaoning high-tech enterprise,wear-resistant overlay welding demostration center of MIIT

♦More than 50 national patents including invention patents

♦Well-equipped laboratory with high-end metallographic analysis equipment, spark- optical emission spectrometer.Carbon sulfur analyzer,spectro-photometer,grain-abrasion testing machine,rockwel hardness apparatus,impacttesting machine

♦Participate in setting wear-resistant pipe standard for DL/T power industry

♦Member of China Welding Association

♦Industry-university-research cooperation enterprise of Liaoning petrochemical University

FAQ

Q1. Are these roller crusher teeth easy to install?

Yes, these teeth are designed for easy installation. They are compatible with most crushers and can be quickly and securely attached.

Q2. How long do these teeth last?

These Chromium Carbide Welding Wear teeth are known for their exceptional wear resistance. With proper maintenance and usage, they can provide longer service life compared to standard teeth, reducing downtime and replacement costs.

Q3. Are these teeth compatible with all types of materials?

Yes, these teeth are built to withstand heavy-duty applications and can effectively crush various materials, including but not limited to minerals, ores, and industrial materials.

Q4. Can I use these teeth on multiple crushers?

These teeth are designed to be compatible with most crushers. However, it is advisable to check the specifications and compatibility of your specific crusher model before purchasing.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)