- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

Chromium Carbide Overlay (CCO) Wear Constructure Parts

Chromium carbide overlay wear resistant construction parts are designed to provide superior protection against wear and abrasion in high-wear applications. These parts are typically made by depositing a layer of chromium carbide onto a base material, such as steel, using a welding process

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Chromium Carbide Overlay Wear Resistant Constructure Parts

Overview:

The chromium carbide overlay layer is extremely hard and wear-resistant, making it ideal for use in applications where parts are subjected to high levels of abrasion, impact, and sliding wear. This layer helps to extend the service life of the construction parts and reduce the need for frequent maintenance and replacement.

Common applications for chromium carbide overlay wear resistant construction parts include conveyor belts, chutes, hoppers, buckets, and other equipment used in mining, construction, and manufacturing industries. These parts are known for their durability, toughness, and resistance to wear, making them a cost-effective solution for protecting critical components from premature wear and failure.

Applications:

| Product Name | Chromium Carbide Overlay Wear Resistant Constructure Parts |

| Material | Q235/Q345+Chromium carbide overlay |

| Hardfacing layer | Chromium carbide overlay;3+3,4+4,5+5,6+4,6+5,6+6,8+4,8+5,8+8,10+10,12+12,16+10,20+20,40+10,etc |

| Chemical composition | C: 3.0-5.0 % Cr: 25-40 % |

| Hardness | HRC58-63 |

| Microstructure | Carbide (Cr7C3)volume fraction above 50 % |

| Wear resistance | High wear/abrasion resistance |

| Thickness tolerance | uniform overlay thickness, with tolerance within 0-0.5 mm |

| Impact resistance | Medium |

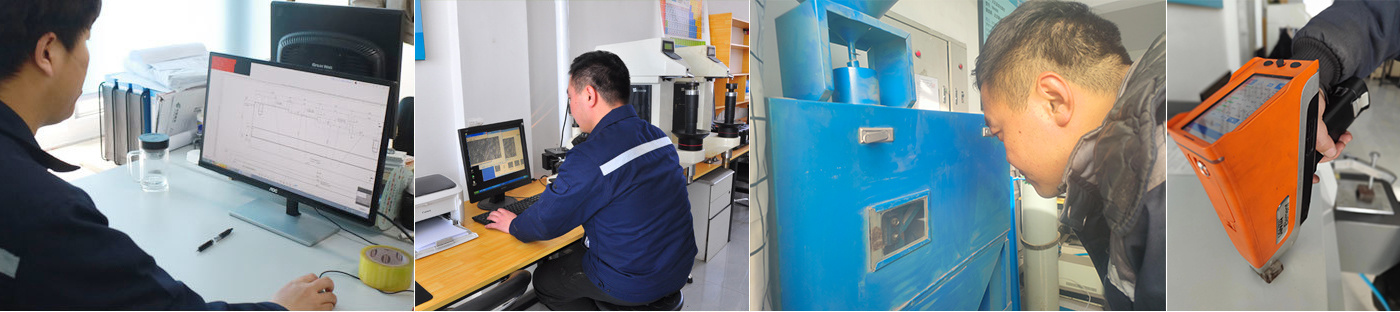

R & D ABILITY

♦Liaoning high-tech enterprise,wear-resistant overlay welding demostration center of MIIT

♦More than 50 national patents including invention patents

♦Well-equipped laboratory with high-end metallographic analysis equipment, spark- optical emission spectrometer.Carbon sulfur analyzer,spectro-photometer,grain-abrasion testing machine,rockwel hardness apparatus,impacttesting machine

♦Participate in setting wear-resistant pipe standard for DL/T power industry

♦Member of China Welding Association

♦Industry-university-research cooperation enterprise of Liaoning petrochemical University

FAQ

Q: What is Chromium Carbide Overlay (CCO)?

A: Chromium Carbide Overlay is a type of wear-resistant material that is applied to surfaces to protect against abrasion, impact, and wear.

Q: What are the benefits of using Chromium Carbide Overlay wear resistant construction parts?

A: Chromium Carbide Overlay parts offer superior wear resistance, increased durability, and extended service life in harsh operating conditions.

Q: What types of construction parts can be made using Chromium Carbide Overlay?

A: Chromium Carbide Overlay can be used to manufacture a wide range of construction parts, including plates, pipes, elbows, liners, and more.

Q: How is Chromium Carbide Overlay applied to construction parts?

A: Chromium Carbide Overlay is typically applied using a welding process, where a layer of chromium carbide is fused to the base material to create a wear-resistant surface.

Q: What industries commonly use Chromium Carbide Overlay wear resistant construction parts?

A: Industries such as mining, construction, cement, steel, and power generation often use Chromium Carbide Overlay parts to protect equipment from wear and abrasion.

Q: How can I ensure the quality of Chromium Carbide Overlay construction parts?

A: It is important to source Chromium Carbide Overlay parts from reputable manufacturers who use high-quality materials and adhere to strict quality control standards.

Q: Are Chromium Carbide Overlay wear resistant construction parts customizable?

A: Yes, Chromium Carbide Overlay parts can be customized to meet specific design requirements and dimensions for different applications.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)