- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

Chromium Carbide Hardfacing Welding Wear Rotor Blades

Rotor blade is mainly used for crushing hot sinter at 700~800℃ at the end of sintering machine. In order to extend the service life of single tooth roller, our company has chosen the method of reforming the metal composition at the worn part of single tooth roller. Chromium carbide overlay composite surface is adopted, and wear-resistant materials are added to the wear-resistant parts. The wear resistant alloy is welded in the worn part by surfacing repair.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Chromium Carbide Hardfacing Welding Wear Rotor Blades

Overview:

Chromium carbide is a hard and wear-resistant material that is ideal for protecting rotor blades in high-wear environments.

By applying a layer of chromium carbide through welding, the rotor blades are able to withstand the abrasive forces that they are subjected to during operation.

The hardfacing process involves carefully preparing the surface of the rotor blades, ensuring that they are clean and free of any contaminants.

The chromium carbide is then applied to the surface of the rotor blades using a welding process, creating a strong bond between the material and the blade.

Once the chromium carbide has been applied, the rotor blades are ready to be put back into operation.

The hardfacing layer provides a protective barrier that helps to extend the lifespan of the rotor blades, reducing the need for frequent replacements and maintenance.

Surface Finish:

Applications:

| Product Name | Chromium Carbide Hardfacing Welding Wear Rotor Blades |

| Material | ZG45/Q235/Q345+Chromium carbide overlay |

| Base metal | ZG45/Q235/Q345 or customized |

| Hardfacing layer | Chromium carbide overlay |

| Chemical composition | C: 3.0-5.0 % Cr: 25-40 % |

| Hardness | HRC57-63 |

| Microstructure | Carbide (Cr7C3)volume fraction above 50 % |

| Wear resistance | High wear/abrasion resistance |

| Hardfacing layer | Chromium carbide overlay;3+3,4+4,5+5,6+4,6+5,6+6,8+4,8+5,8+8,10+10,12+12,16+10,20+20,40+10,etc |

| Main Application | Mining, Steel, Cement, Power, Port, Glass, Coal, etc. |

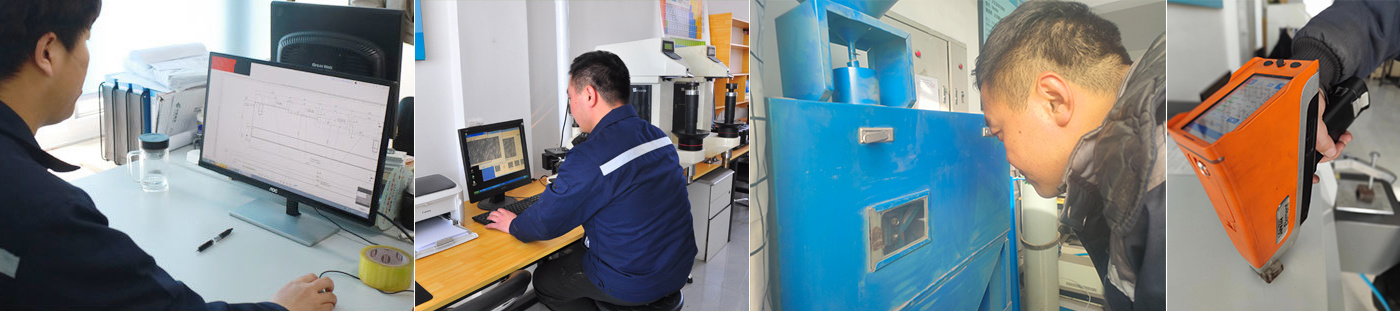

R & D ABILITY

♦Liaoning high-tech enterprise,wear-resistant overlay welding demostration center of MIIT

♦More than 50 national patents including invention patents

♦Well-equipped laboratory with high-end metallographic analysis equipment, spark- optical emission spectrometer.Carbon sulfur analyzer,spectro-photometer,grain-abrasion testing machine,rockwel hardness apparatus,impacttesting machine

♦Participate in setting wear-resistant pipe standard for DL/T power industry

♦Member of China Welding Association

♦Industry-university-research cooperation enterprise of Liaoning petrochemical University

FAQ

Q: Are these rotor blades suitable for heavy-duty industrial use?

A: Yes, our Chromium Carbide Hardfacing Welding Wear Rotor Blades are specifically designed for heavy-duty cutting and grinding applications in industrial settings.

Q: Can these blades be used with all types of cutting and grinding tools?

A: Yes, these rotor blades have a universal fit and can be easily attached to a wide range of cutting and grinding tools.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)