- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

Chromium Carbide Hardfacing Welding Wear Grizzly Bar

Grizzly bar is one of the main wear-resistant parts of the single-tooth roller crusher. Because its working temperature is as high as 800℃ and it can bear large thermal load and impact load at the same time, it is subjected to complex forces and serious wear. It can greatly improve the abrasion resistance and service life of grate plate by surfacing overlay welding.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Chromium Carbide Hardfacing Welding Wear Grizzly Bar

Overview:

Chromium carbide hardfacing welding wear grizzly bars are used in heavy-duty applications to protect equipment from wear and abrasion.

Be made from a combination of chromium carbide overlay and mild steel, which provides excellent resistance to abrasion and impact.

The hardfacing welding process involves applying a layer of chromium carbide to the surface of the bar, which creates a tough and durable protective coating.

Grizzly bars are commonly used in industries such as mining, construction, and recycling, where equipment is subjected to high levels of wear and tear.

Applications:

| Product Name | Chromium Carbide Hardfacing Welding Wear Grizzly Bar |

| Material | Q235/Q345+Chromium carbide overlay |

| Base metal | Q235/Q245 or customized |

| Hardfacing layer | Chromium carbide overlay |

| Chemical composition | C:3.0-5.0% Cr:25-40% |

| Hardness | HRC58-63 |

| Microstructure | Carbide (Cr7C3)volume fraction above 50% |

| Wear resistance | Hihg wear/abrasion resistance |

| Flatness tolerance | ±3 mm/m |

| Thickness tolerance | uniform overlay thickness,with tolerance within 0-0.5mm |

| Impact resistance | Medium |

| Technology | Hardfacing,open arc welding ,submerged arc welding |

| Plate size | Customized size |

| Main thickness(base metal+overlayer ) | Customized thickness |

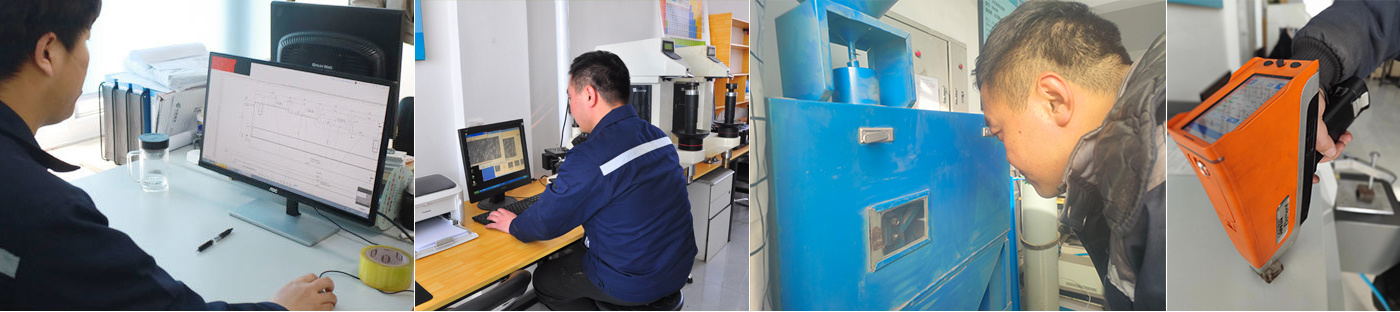

R & D ABILITY

♦Liaoning high-tech enterprise,wear-resistant overlay welding demostration center of MIIT

♦More than 50 national patents including invention patents

♦Well-equipped laboratory with high-end metallographic analysis equipment, spark- optical emission spectrometer.Carbon sulfur analyzer,spectro-photometer,grain-abrasion testing machine,rockwel hardness apparatus,impacttesting machine

♦Participate in setting wear-resistant pipe standard for DL/T power industry

♦Member of China Welding Association

♦Industry-university-research cooperation enterprise of Liaoning petrochemical University

FAQ

Q1. What is chromium carbide hardfacing welding?

A1.Chromium carbide hardfacing welding is a process in which a layer of chromium carbide is applied to a metal surface using welding techniques. This layer of chromium carbide is extremely hard and wear-resistant, making it ideal for applications where the metal surface is subject to abrasive wear.

Q2. What are the benefits of chromium carbide hardfacing welding?

A2.Some of the benefits of chromium carbide hardfacing welding include increased wear resistance, improved durability, and extended service life of the metal surface. This process can also help to reduce maintenance costs and downtime associated with equipment failure due to wear.

Q3. What are grizzly bars and how are they used?

A3.Grizzly bars are heavy-duty metal bars that are typically used in mining and aggregate industries to sort and separate materials. They are often subject to high levels of abrasion and impact, which can cause them to wear out quickly. Chromium carbide hardfacing welding can be used to protect grizzly bars from wear and extend their service life.

Q4. How is chromium carbide hardfacing welding applied to grizzly bars?

A4.Chromium carbide hardfacing welding is typically applied to grizzly bars using a welding process such as flux-cored arc welding or gas metal arc welding. The chromium carbide material is applied in layers to build up a thick, wear-resistant coating on the surface of the grizzly bar.

Q5. How long does chromium carbide hardfacing welding last on grizzly bars?

A5.The service life of chromium carbide hardfacing welding on grizzly bars can vary depending on factors such as the application, operating conditions, and maintenance practices. In general, chromium carbide hardfacing welding can significantly extend the service life of grizzly bars compared to untreated bars.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)