- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

Chromium Carbide Hardfacing Welding Wear Grinding Table

Chromium Carbide Grinding TableDuring the use of the vertical grinding roller body and the wear-resistant table lining, the rolling pressure of the roller, the supporting force of the material, and the frictional resistance between the material and the grinding roller lining will increase the severe abrasion between the body and the lining, the liner will crack or even break. Our Chromium Carbide Wear Grinding Table adopts chromium carbide bimetallic composite material to carry out hard surface wear-resistant overlay welding on the surface of the roller body, or repair the surface of the tires that have been worn, to solve the problem satisfactorily.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Chromium Carbide Hardfacing Welding Wear Grinding Table

Overview:

Chromium Carbide Hardfacing Welding Wear Grinding Table ,The surfacing welding can effectively repair the wear on the surface of the equipment.

Hardfacing Grinding Table improve the service life and operation efficiency of the equipment, and improve production efficiency and product quality.

Welding Grinding Table has the advantages of high flexibility, good economy and good repair effect. Widely used in steel, mining, electricity, cement, metallurgy, glass, building materials and other industries, for the maintenance and maintenance of important equipment is of great significance.

Surface Finish:

Applications:

| Product Name | Grinding roller table for wear resistance parts |

| Base Material | Q235/Q345/ZG45 |

| Overlay Material | Chromium carbide overlay |

| Thickness | 3+3,5+5,6+4,6+5,8+4,8+8,10+10,16+10,etc |

| Chemical composition | C:3.0-5.0%Cr:25-40% |

| Technology | Hardfacing,open arc welding,submerged arcwelding |

| Application | Mining,Steel,CementPower,PortCoal,etc |

| Hardness | HRC58-63 |

| Microstructure | Carbide (Cr7C3)volume fraction above 50 % |

| Flatness tolerance | ±3 mm/m |

| Thickness tolerance | uniform overlay thickness, with tolerance within 0-0.5 mm |

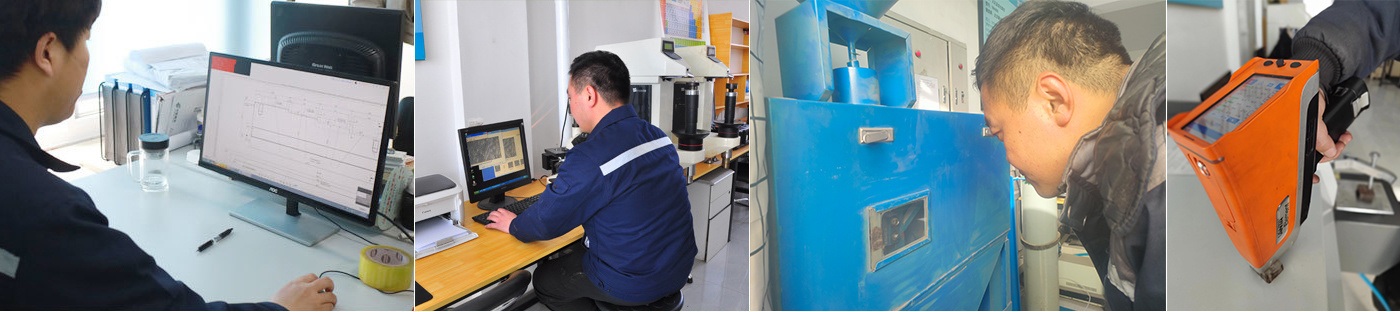

R & D ABILITY

♦Liaoning high-tech enterprise,wear-resistant overlay welding demostration center of MIIT

♦More than 50 national patents including invention patents

♦Well-equipped laboratory with high-end metallographic analysis equipment, spark- optical emission spectrometer.Carbon sulfur analyzer,spectro-photometer,grain-abrasion testing machine,rockwel hardness apparatus,impacttesting machine

♦Participate in setting wear-resistant pipe standard for DL/T power industry

♦Member of China Welding Association

♦Industry-university-research cooperation enterprise of Liaoning petrochemical University

FAQ

Q: What are the advantages of using the Chromium Carbide Hardfacing Welding Wear Grinding Table?

A: This grinding table offers exceptional durability, superior performance, and versatility. Its wear-resistant properties ensure a longer lifespan for your equipment while improving grinding efficiency.

Q: Can this grinding table be used with different types of grinding equipment?

A: Yes, our hardfacing welding wear grinding table is designed to be compatible with various grinding equipment, including vertical roller mills and ball mills.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)