- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

Chromium Carbide Hardfacing Welding Wear Coal Hopper

During operation, Chromium Carbide Hardfacing Welding Wear Coal Hopper through the designated opening. The chromium carbide hard facing coating protects the hopper's interior surface, preventing erosion and wear caused by the abrasive nature of the raw materials.

This results in an extended lifespan of the hopper, reducing the need for frequent replacements and minimizing downtime.

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

Chromium Carbide Hardfacing Welding Wear Coal Hopper

Overview:

The Chromium Carbide Hard facing Welding Wear Hopper effectively addresses the issue of wear and tear caused by coal and other abrasive materials.

By utilizing the superior wear resistance properties of chromium carbide hard facing, this hopper withstands the rigorous demands of handling process.

Surface Finish:

Applications:

| Product Name | Chromium Carbide Hardfacing Welding Wear Coal Hopper |

| Base metal | Q235/Q345+Chromium carbide overlay |

| Hardfacing layer | Chromium carbide overlay;3+3,4+4,5+5,6+4,6+5,6+6,8+4,8+5,8+8,10+10,12+12,16+10,20+20,40+10,etc |

| Chemical composition | C: 3.0-5.0 % Cr: 25-40 % |

| Hardness | HRC58-63 |

| Microstructure | Carbide (Cr7C3)volume fraction above 50 % |

| Wear resistance | High wear/abrasion resistance |

| Thickness tolerance | uniform overlay thickness, with tolerance within 0-0.5 mm |

| Impact resistance | Medium |

| Technology | Hardfacing, open arc welding, submerged arc welding |

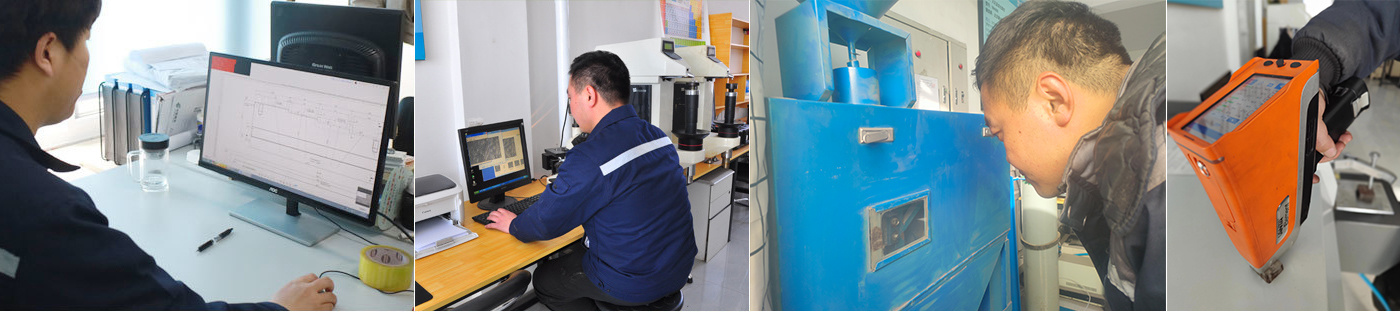

R & D ABILITY

♦Liaoning high-tech enterprise,wear-resistant overlay welding demostration center of MIIT

♦More than 50 national patents including invention patents

♦Well-equipped laboratory with high-end metallographic analysis equipment, spark- optical emission spectrometer.Carbon sulfur analyzer,spectro-photometer,grain-abrasion testing machine,rockwel hardness apparatus,impacttesting machine

♦Participate in setting wear-resistant pipe standard for DL/T power industry

♦Member of China Welding Association

♦Industry-university-research cooperation enterprise of Liaoning petrochemical University

FAQ

Q: Is this hopper suitable for handling materials other than coal?

A: While this hopper is specifically designed for coal handling applications due to its exceptional wear resistance, it can also be utilized for other abrasive materials with similar characteristics.

Q: Can this hopper be customized to meet specific requirements?

A: Yes, we offer customization options to meet your specific needs. Please contact our customer support team for further details.

Q: Is the installation process complex?

A: Installing the Chromium Carbide Hard facing Welding Wear Coal Hopper is straightforward and hassle-free. Detailed instructions are provided with the product, ensuring easy integration with your existing coal handling system.

Q: What is the expected lifespan of this hopper?

A: The chromium carbide hard facing coating significantly increases the hopper's lifespan, reducing the need for frequent replacements. However, the actual lifespan may vary depending on factors such as usage frequency, material handled, and operating conditions.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)