- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

HP200 (Resistance to medium impact abrasive wear)

Chromium Carbide Overlay Wear Resistant Steel Plate eutectic structure, which make the wear resistance of hard-faced wear resistant steel plate reached 14.6 times more than A36/SS400 steel plate.( Abrasive wear test as per ASTM G65)

- hard-plate

- China

- depend on quantity

- 6000 Tons

Details

HP200

Weld Overlay Wear Plates Chromium Carbide Overlay (CCO) Wear Plates

Overview:

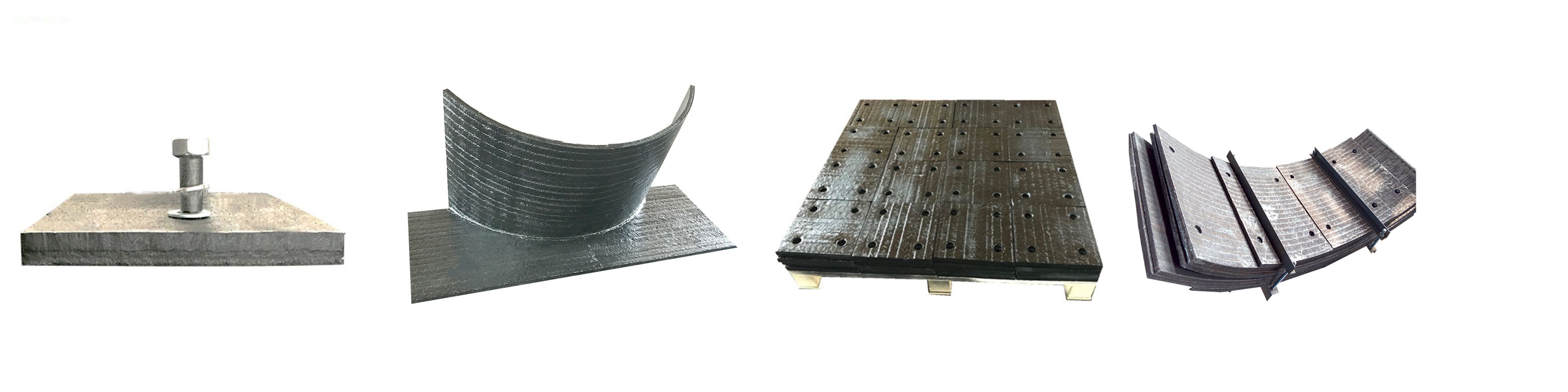

HP200 Chromium Carbide Plate (CCO Plate ) Welding Wear Resistant Plate has high hardness and excellent wear-resistant performance.

The base metal is a common rolled plate with good toughness and plasticity.

The wear-resistant alloy layer and the base metal are metallurgy combined and firmly combined in service,wear is resisted by the high hardness of the surface allov aver.

And the impact of external force is resisted by the strength and toughness of the matrix.

Wear Resistant Plate( CCO Plate ) Specification:

| Wear Resistant Plate Material | High-quality wear plate with a Chromium Carbide Overlay Welding layer |

| Sheet size | 1400*3000mm, 2100*3000mm /Customizied |

| Thickness | 3+3mm, 4+4mm, 5+5mm,6+6mm....20+20mm, 40+30mm /Customizied |

| Hardness | HRC 58-63 |

Surface Finish:

Applications:

| Model | HRC | Working Temperature | Wear Plate Alloy Chemical Composition(%) | Wear Plate (CCO Plate)specification and thickness(mm) | ||||

| C | Cr | Mn | Nb | Others | ||||

| HP100 | 60-63 | >500°C | 3-5 | 22-28 | 48 | 4+4 4+5 6+5 8+8 8+6 8+8 10+5 10+6 10+7 10+8 10+10 12+5 12+6 12+8 12+10 12+12 14+6 14+8 14+10 16+4 16+6 16+8 16+10 16+12 | ||

| HP200 | 58-62 | >500°C | 3-5 | 20-26 | 1-3 | 2-5 | ||

| HP300 | 60-65 | >800°C | 4-6 | 18-25 | 2-3 | 5-8 | 3-6 | |

| HP400 | 50-55 | >500°C | 0.4-2 | 3-7 | 15-20 | 2-5 | ||

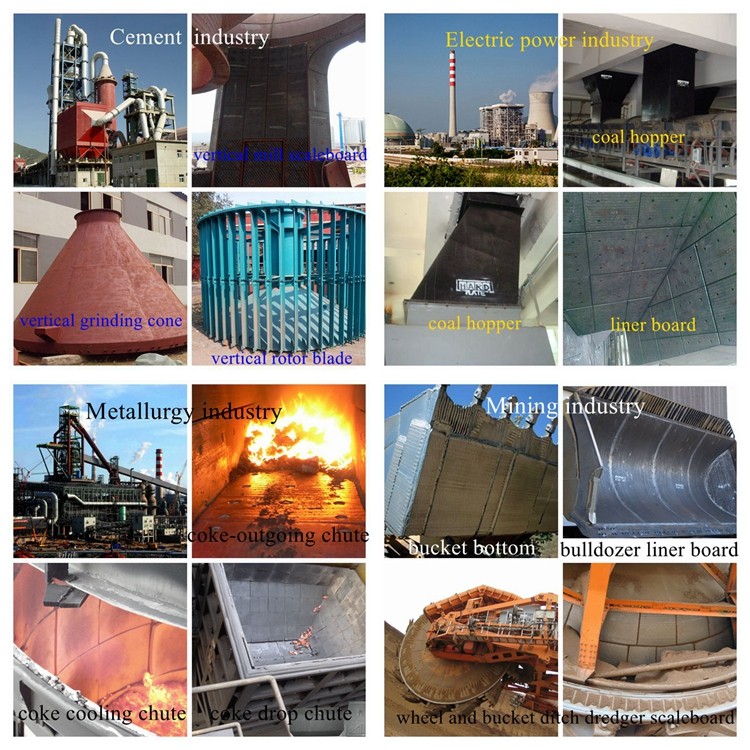

Industry Application | Mining Industry | Excavator bucket liners, bucket-wheel excavator, scarper conveyor middle trough, elevator skip, hopper liner | ||||||

| Iron and steel industry | Bin liner, skip car liner, vibrating feeder lining, CDQ tank lining, coke-barrier car bottom plate, slag sluice lining | |||||||

| Cement industry | Raw mill lining, clinker chute lining, dust discharge pipe, guide vane, roller protection sleeve, slag mill wear parts | |||||||

| Power industry | Coal hopper lining plate , coal drop pipe liners, coal mill wear parts, ash pipeline, fan blade | |||||||

| Engineering industry | Shield machine wear parts, boring machine shovel plate, loader shovel plate, dump truck body plate | |||||||

| Glass industry | Blender mixer bottom plate, fan blade, fore and rear discs of fan impeller, quick-wearing wear parts | |||||||

| Port Industry | Loading and discharging machine, wear-resistant pipeline, channel dredging, bin liner | |||||||

| We also customize various specification CCO plate and wear parts according to customer requirement and drawings. | ||||||||

Fabrication:

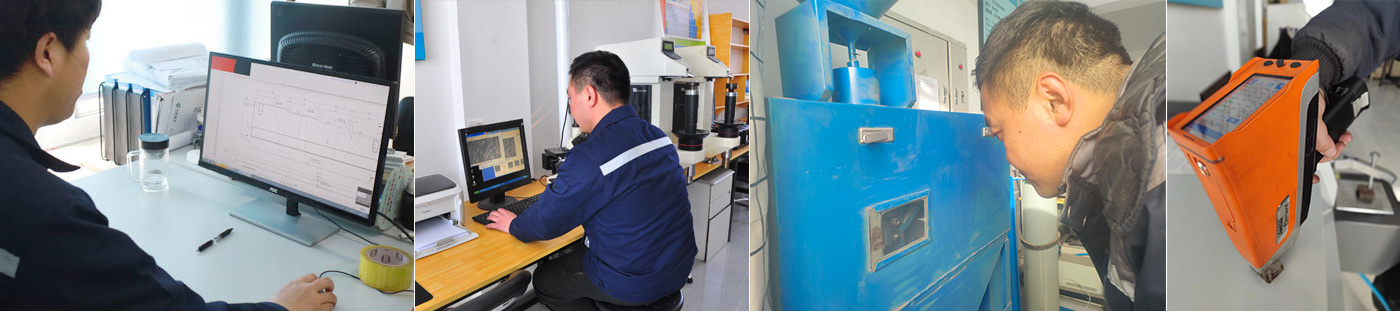

R & D ABILITY

♦Liaoning high-tech enterprise,wear-resistant overlay welding demostration center of MIIT

♦More than 50 national patents including invention patents

♦Well-equipped laboratory with high-end metallographic analysis equipment, spark- optical emission spectrometer.Carbon sulfur analyzer,spectro-photometer,grain-abrasion testing machine,rockwel hardness apparatus,impacttesting machine

♦Participate in setting wear-resistant pipe standard for DL/T power industry

♦Member of China Welding Association

♦Industry-university-research cooperation enterprise of Liaoning petrochemical University

FAQ

Q1: Why are there so many cracks?

A1. Due to the cooling rates of dissimilar metals. Our hard facing plate for coal chute liner is manufactured by welding which results in high temperatures. During the cooling, the plate goes through a stress relieving which is a natural process and does not effect the performance of the plate. The stress relief cracks should be between 3/4" - 2" apart. The cracks can be touched up by our chrome carbide welding rod.

Q2: What is the best method of attachment?

A2. hard facing plate for coal chute liner is usually attached by countersunk bolts, welding studs, perimeter welding, or plug welding. Some methods are better suited than others depending on the specific application. For more detail on each method see the installation section.

Q3: Can hard facing plate for coal chute liner be drilled or machined?

A3. hard facing plate for coal chute liner cannot be machined or drilled. It can however be ground. Mild steel inserts are used to create countersunk or counter bored holes. hard facing plate for coal chute liner can be cut using plasma, Grinding wheel saw, or air-arc gouging.

Q4:MOQ?

A4.Our product has no limit to quantity, it can be ordered according to customer requirement.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)