- Home

-

Products

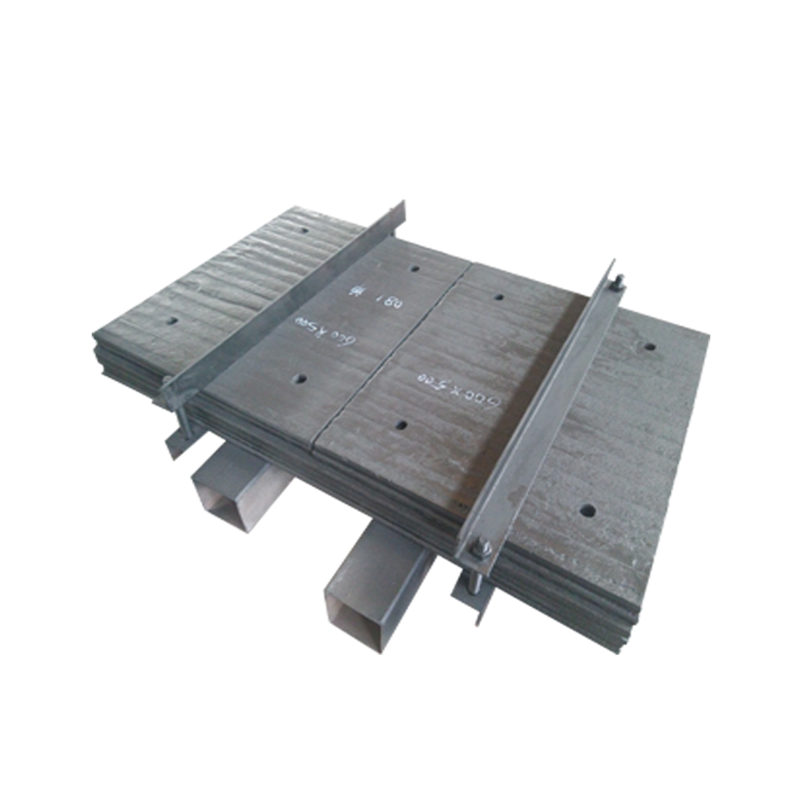

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

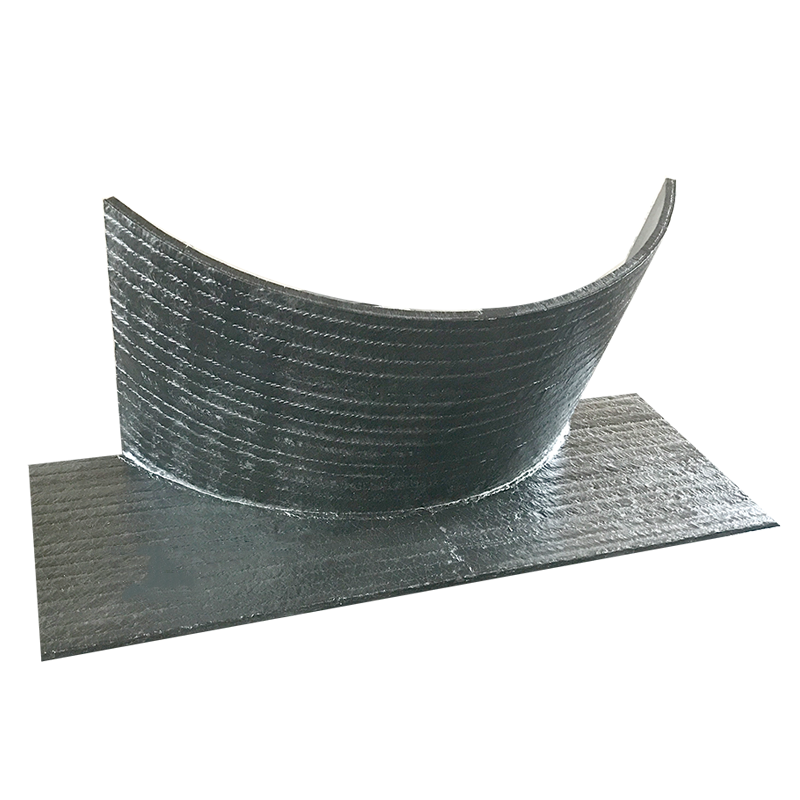

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

How to identify the quality of wear-resistant steel plates?

2023-11-22 16:40

Appearance Quality

1. Flatness: The four corners of the flat plate are on the ground,

2. Welding cracks: evenly spaced, small cracks, not wide;

3. hardfacing layer: no obvious unevenness

4. Welding defects: within a reasonable range;

5. Surface spray paint: the paint layer is evenly thin and thick, putty, etc.;

6. Edge cutting on all sides: straight, no burrs; the large plasma cutting machine is well formed,

Intrinsic quality

1. Wear-resistant layer thickness: Measured after polishing, the hardfacing layer is obvious, take multi-point measurement and average value;

2. The total thickness of the steel plate: controlled within the allowable range, ±0.5mm

3. Hardness: within the required range, HRC55-62

4. Composition: alloy composition;

5. Metallography: Metallographic analysis;

Get the latest price? We'll respond as soon as possible(within 12 hours)