- Home

-

Products

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

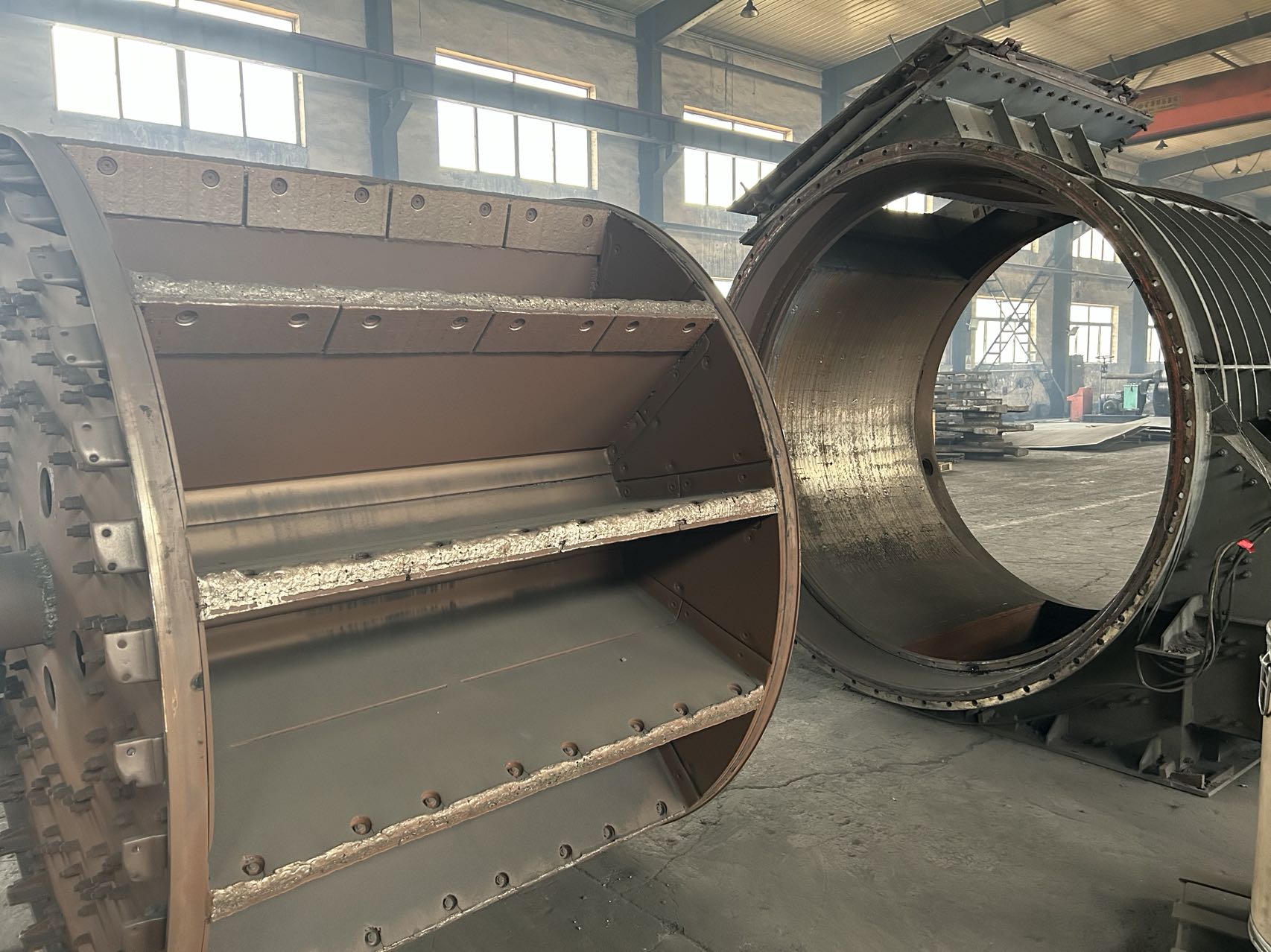

CDQ rotary sealing valve repair for coke plant

CDQ rotary sealing valve is the key equipment in CDQ project of coking plant. Its function is to continuously discharge the coke quantitatively discharged by the vibrating feeder in a closed state. It can not only discharge continuously and quantitatively, but also has good sealing. It can effectively control the leakage of circulating gas and dust in the CDQ furnace, and stabilize the pressure of circulating gas in the CDQ furnace.

Hard-Plate makes customized repair plan according to the actual abrasion condition, using chromium carbide overlay material for the tailored fabrication to fix it up.

Get the latest price? We'll respond as soon as possible(within 12 hours)