- Home

-

Products

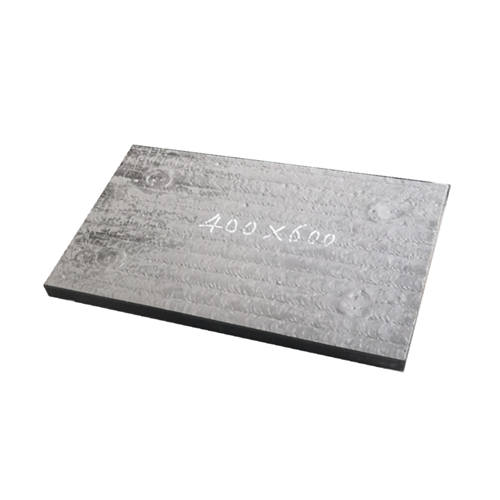

- Chromium Carbide Overlay (CCO) Wear Plates

- Chromium Carbide Overlay (CCO) Wear Pipes & Fittings

- Hardfacing Flux Cored Welding Wires

- Self-Shielded Flux Cored Welding Wire

- Gas Shielded Flux Cored Welding Wire

- Submerged Arc Flux Cored Welding Wire

- Chromium Carbide Overlay (CCO) Wear Parts

- Chromium Carbide Overlay (CCO) Wear Constructure Parts

- Chromium Carbide Overlay (CCO) Wear Hopper

- Chromium Carbide Overlay (CCO) Wear Grinding Roller

- Chromium Carbide Overlay (CCO) Wear Grinding Table

- Chromium Carbide Overlay (CCO) Wear Chute

- Chromium Carbide Overlay (CCO) Wear Rotor Blades

- Chromium Carbide Overlay (CCO) Wear Grizzly Bar

- Chromium Carbide Overlay (CCO) Wear Single Roller Teeth

- Chromium Carbide Overlay (CCO) Wear Liner

- News

- Case

- Factory Show

- Contact Us

- About Us

Why choose chromium carbide as a wear layer material?

2024-05-16 14:37

The wear resistance of chromium carbide materials is due to their unique microstructure and composition. Chromium carbide is a hard and wear-resistant material that is formed when chromium atoms bond with carbon atoms. This combination results in a material that is extremely hard and resistant to abrasion.

The microstructure of chromium carbide materials is characterized by a network of chromium carbide particles embedded in a matrix of softer material, such as steel. This structure provides the material with both hardness and toughness, making it ideal for applications where wear resistance is crucial.

The hardness of chromium carbide materials comes from the strong covalent bonds between chromium and carbon atoms. These bonds are extremely resistant to deformation, making the material highly resistant to wear and abrasion. In addition, the presence of carbides in the material further enhances its wear resistance, as carbides are known for their hardness and resistance to wear.

Furthermore, chromium carbide materials have excellent thermal stability, allowing them to maintain their wear resistance even at high temperatures. This makes them suitable for a wide range of applications, including cutting tools, wear plates, and other components that are subjected to high levels of wear and abrasion.

In conclusion, the wear resistance of chromium carbide materials is a result of their unique microstructure, composition, and thermal stability. These materials are highly durable and resistant to wear, making them an excellent choice for applications where wear resistance is a critical factor.

Get the latest price? We'll respond as soon as possible(within 12 hours)